ENGR338 Lab Spring 2021

Lab 5: The Inverter

Name: Audra Benally

Email: albenally1@fortlewis.edu

1. Title: The Inverter

2. Introduction: In this lab, we built an inverter in schematic and

layout view. This inverter had a PMOS with a width of 20 and an NMOS

with a width of 10. Next we used this first inverter to make a larger

inverter using the multiplier function in ElectricVLSI. The layout for

the larger inverter had a PMOS of width 100 and an NMOS of width 50.

The two inverters were connected to different sized capacitors and

simulated to test their driving capabilities. New built-in simulation tools were introduced in this lab as well.

3. Materials and Methods:

Materials:

- Computer

- LTSpice Software

- ElectricVLSI Software

Methods:

For this lab

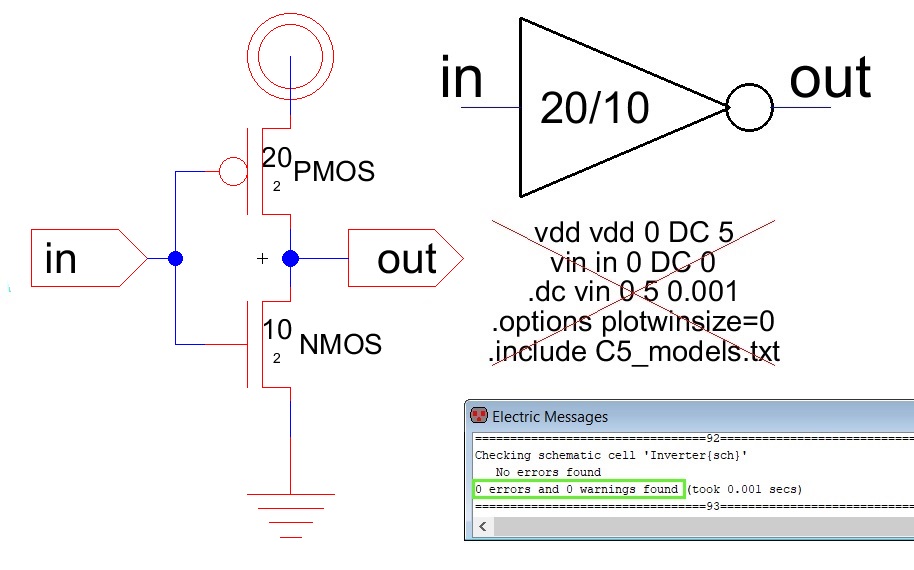

we created two different versions of a PMOS/NMOS inverter. The first

inverter was a 20/10 inverter with 20/2 PMOS and 10/2 NMOS components.

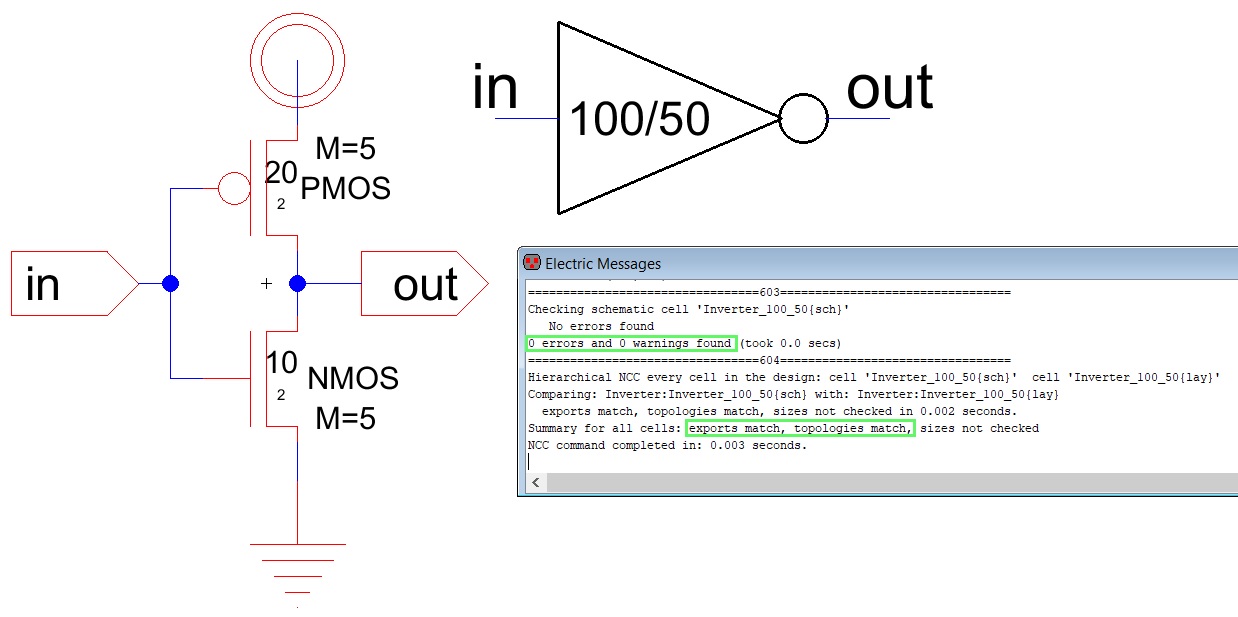

The inverter was built in schematic view as seen in figure 1 first,

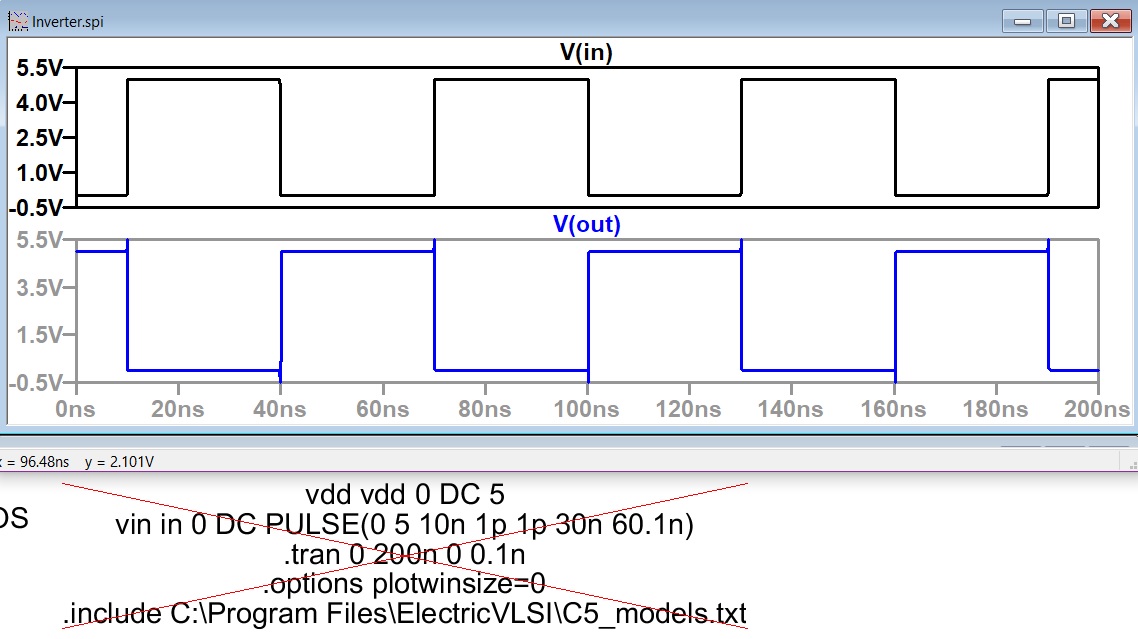

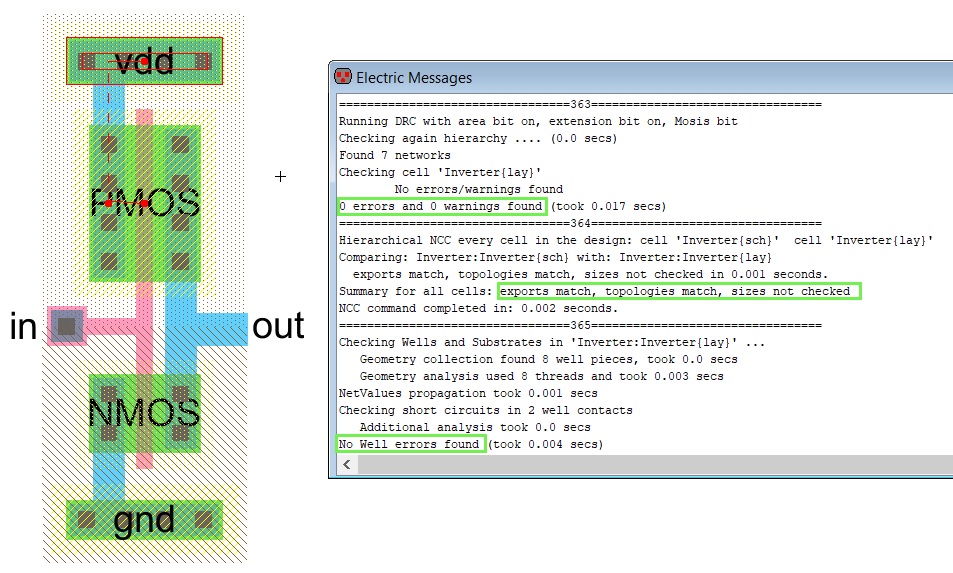

then in layout view which can be seen in figure 3. After schematic view

was made, code was added and simulated to show the simulation in figure

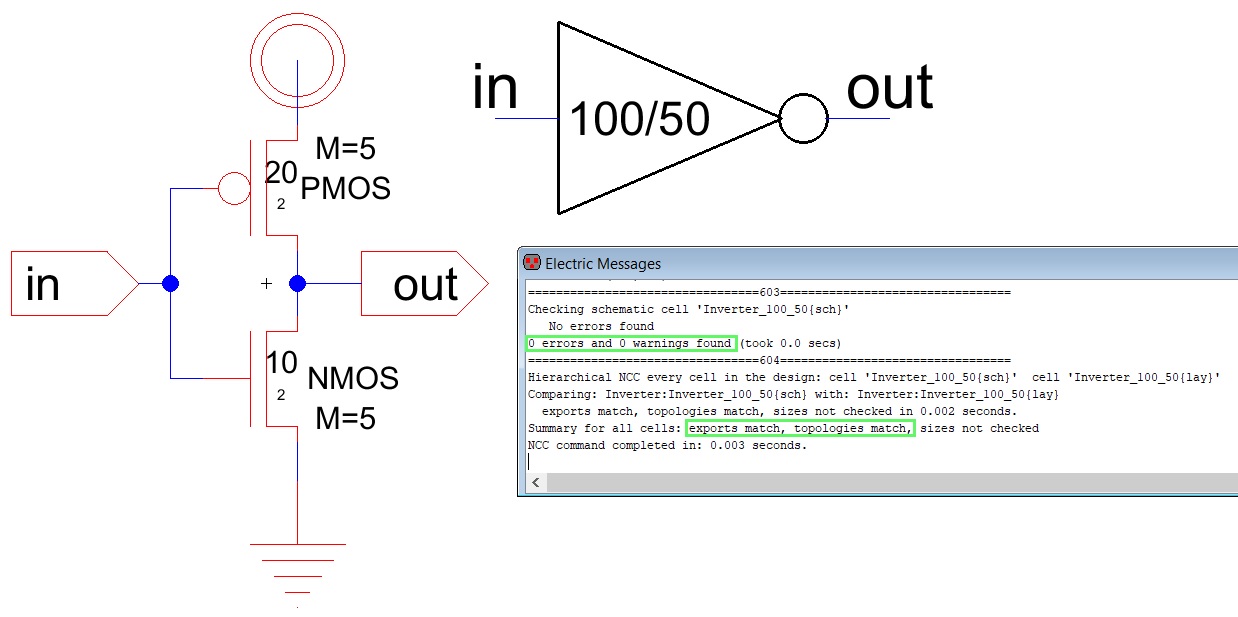

2. Then, a new inverter was made using the schematic of the first

inverter. A 5x multiplier was added through tools that turned the old

components into a 100/10 PMOS and a 50/10 NMOS. In the layout view the

PMOS and the NMOS were both duplicated and lengthened to what is now

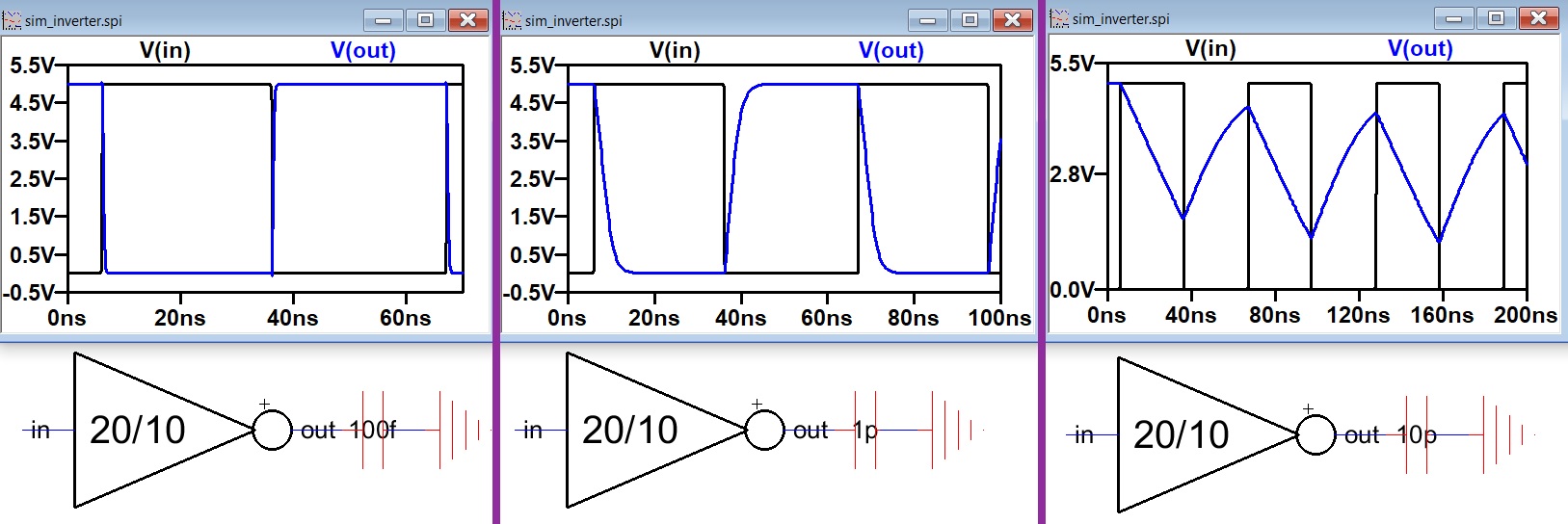

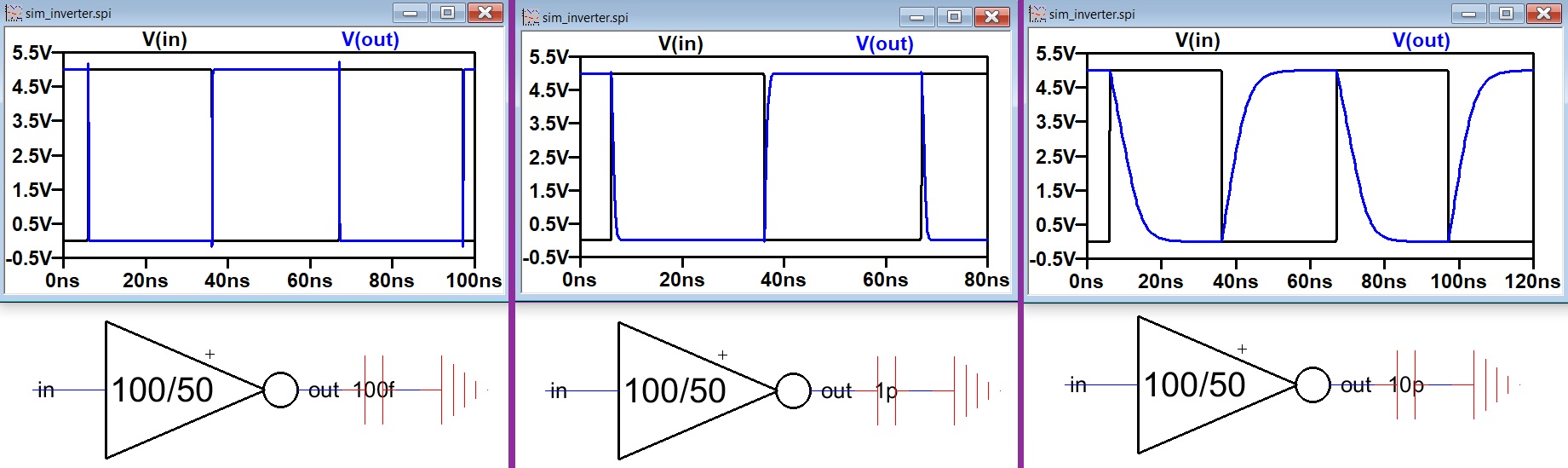

shown in figure 5. Both inverters were simulated with three different

capacitors. The first had a capacitance of 100fF, the second was 1pF,

and the third was 10pF. The simulations for the first 20/10 inverter is

seen in figure 6 while the simulation for the 100/50 inverter can be

seen in figure 7. For the last task, different simulation tools were

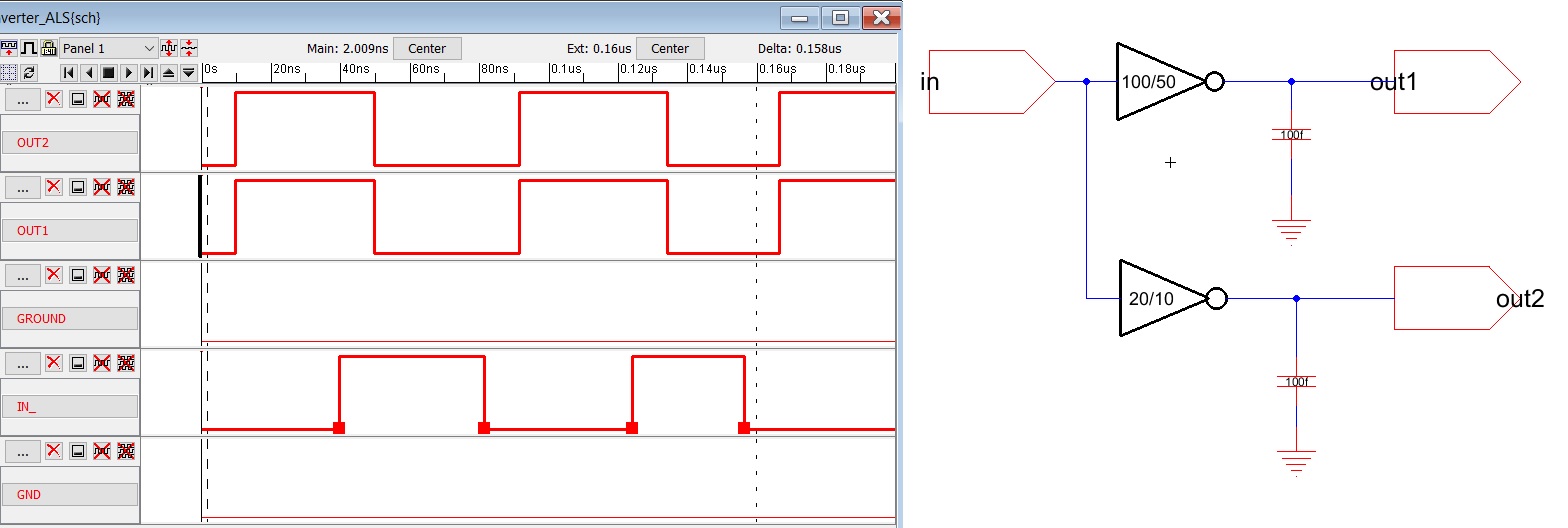

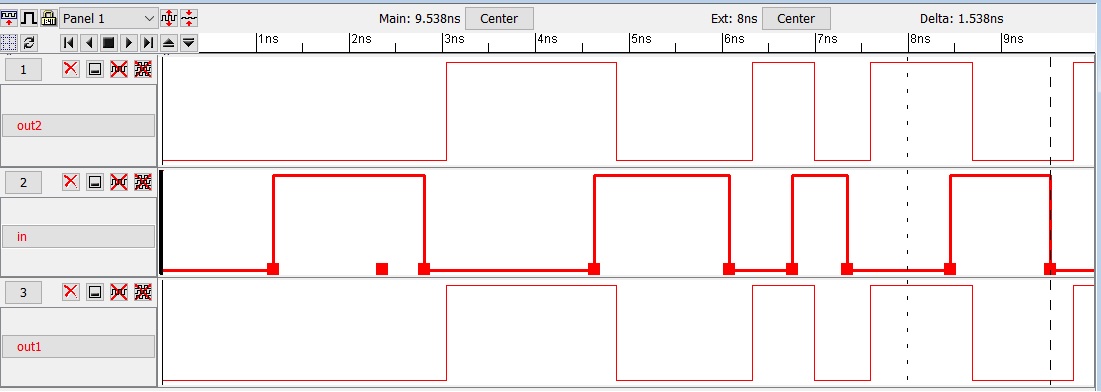

used to test the two inverters. Figure 8 shows the ALS simulation tool

while figure 9 shows the same simulation with the IRSIM simulation tool.

4. Results:

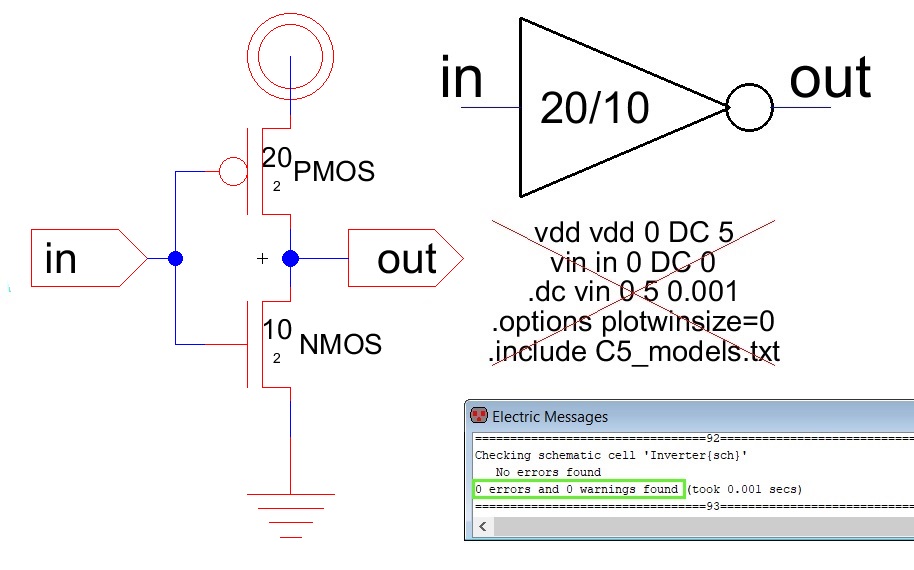

Figure 1. Inverter schematic for the first 20/10 inverter.

Figure 2.

Modified spice code to run a transient simulation using a PULSE()

Vinput.

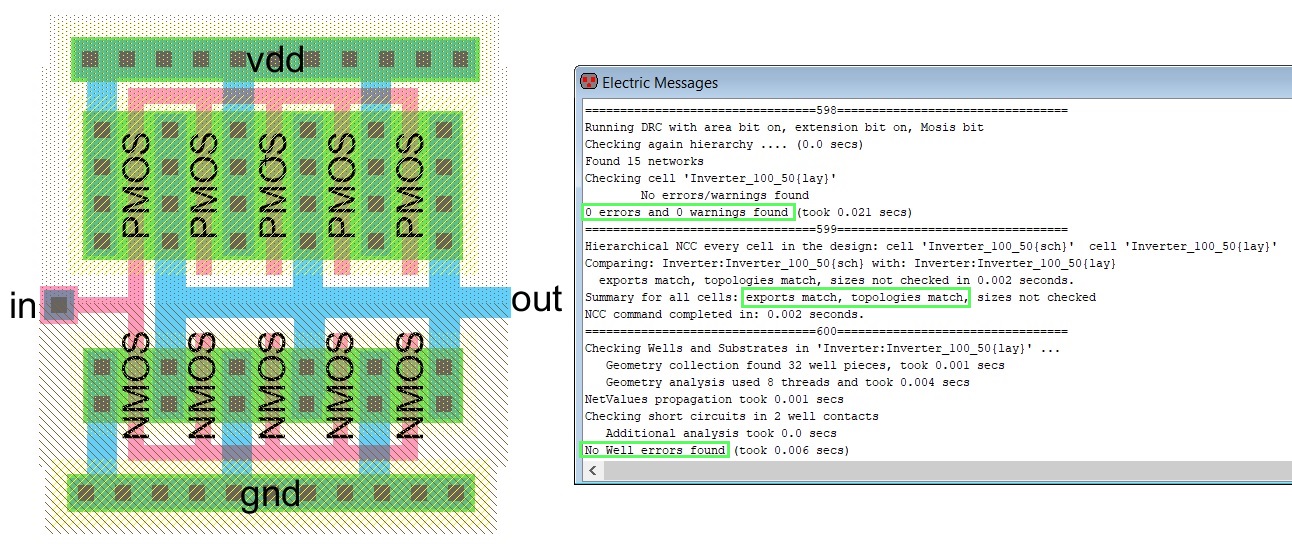

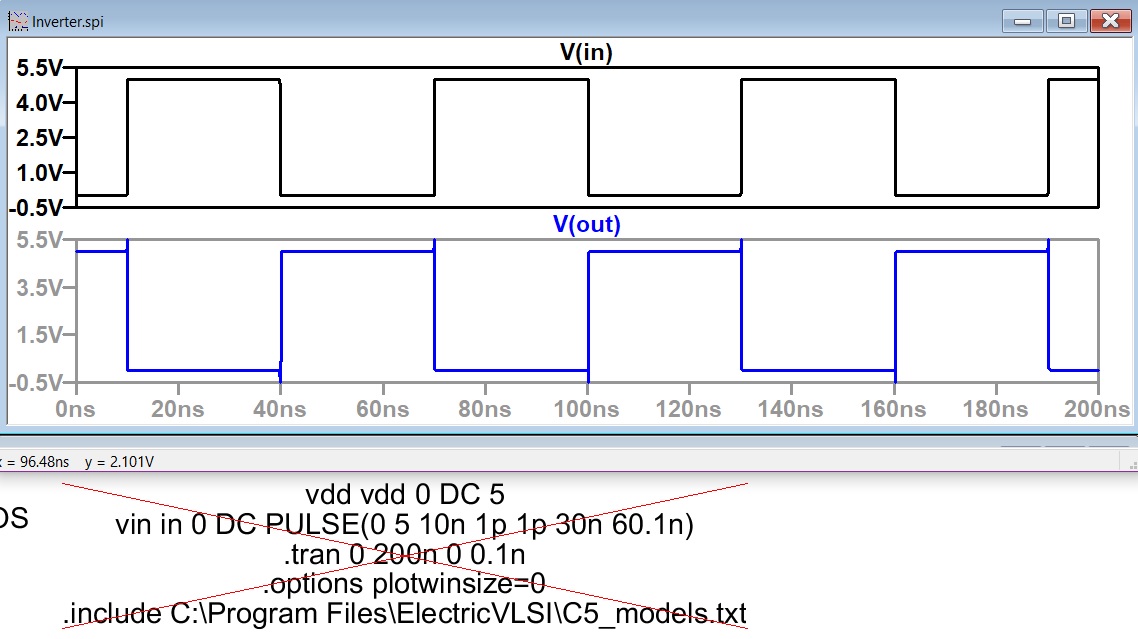

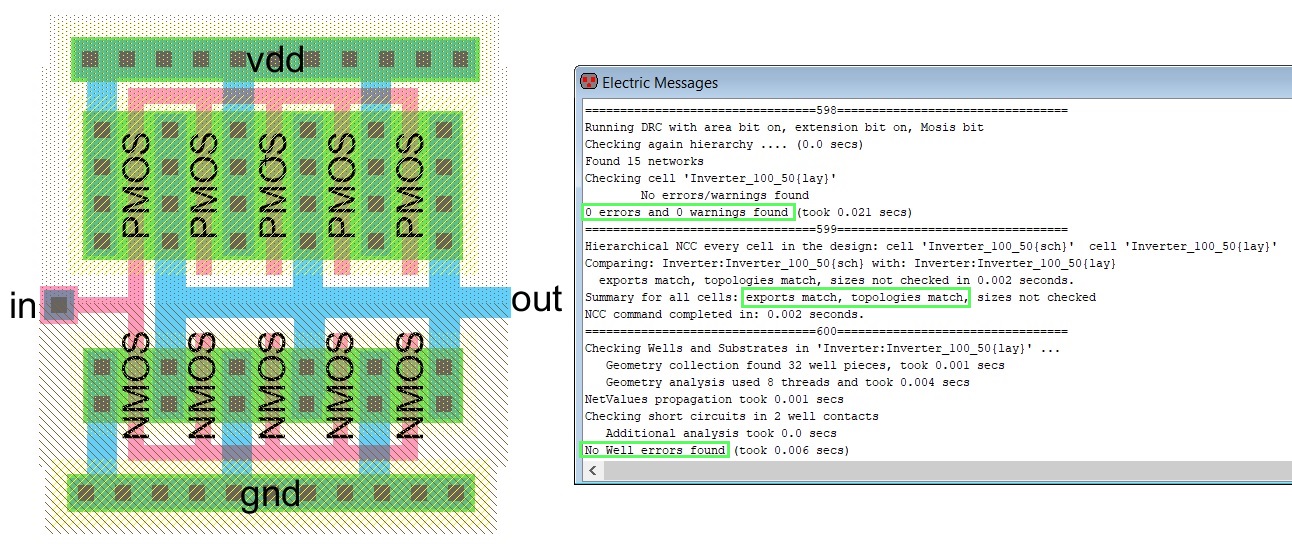

Figure 3.

20/10 Inverter layout with DRC, NCC, and well check results highlighted.

Figure 4.

100/50 Inverter schematic made from 20/10 schematic with M=5.

Figure 5.

100/50 Inverter layout with DRC, NCC, and well check results

highlighted.

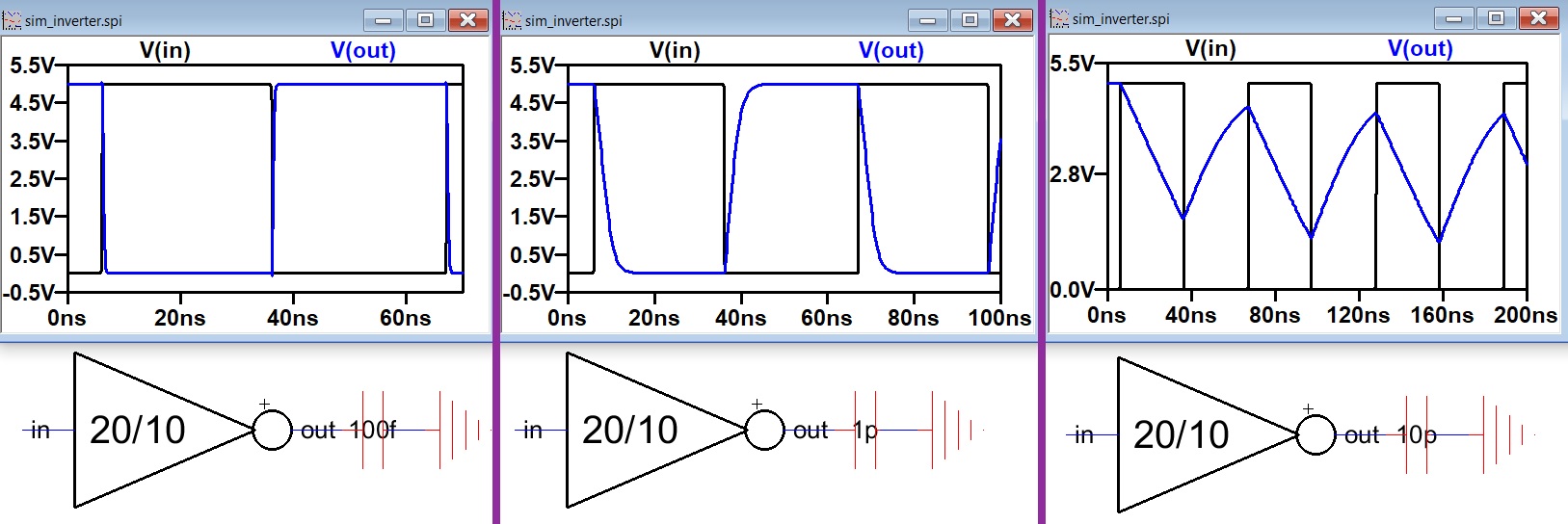

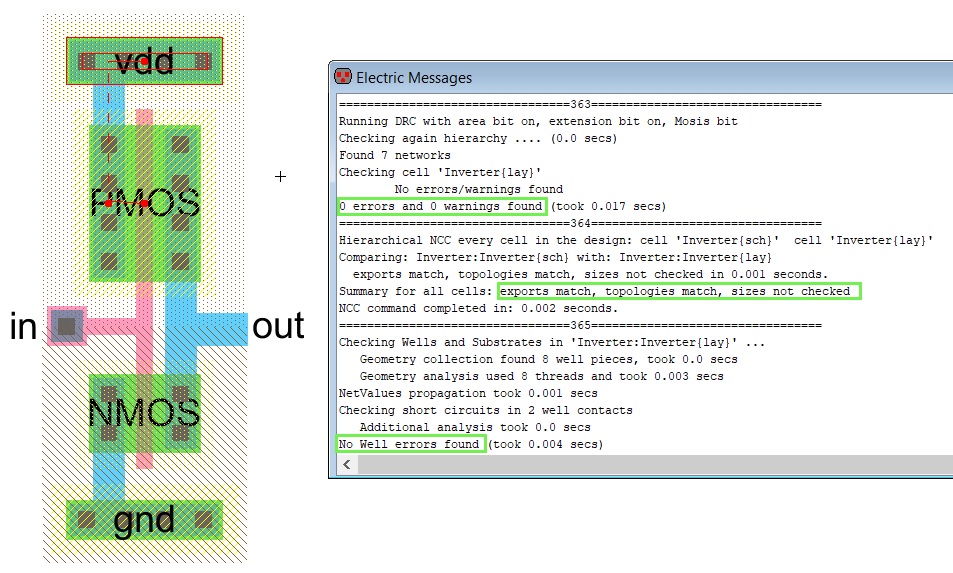

Figure 6.

20/10 Inverter with different capacitors and the resulting Vin/Vout

simulations. The simulations show the inverter's driving capabilities.

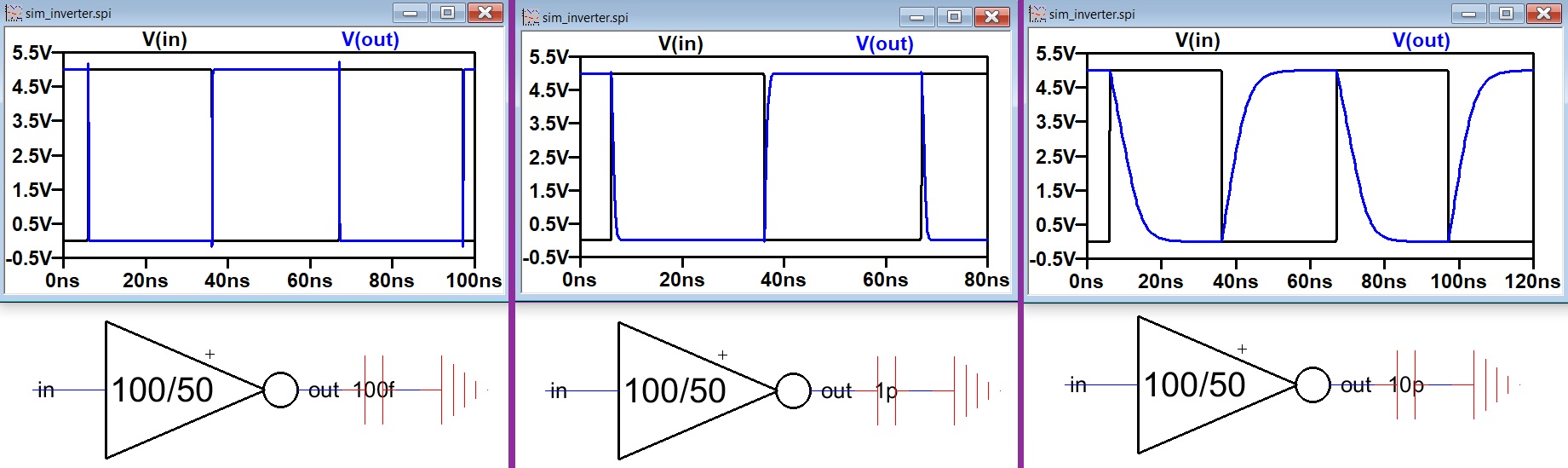

Figure 7.

100/50 Inverter connected to the same capacitors as the 20/10 inverter.

The resulting simulations are grouped with their schematics. The

simulations show the inverter's driving capabilities.

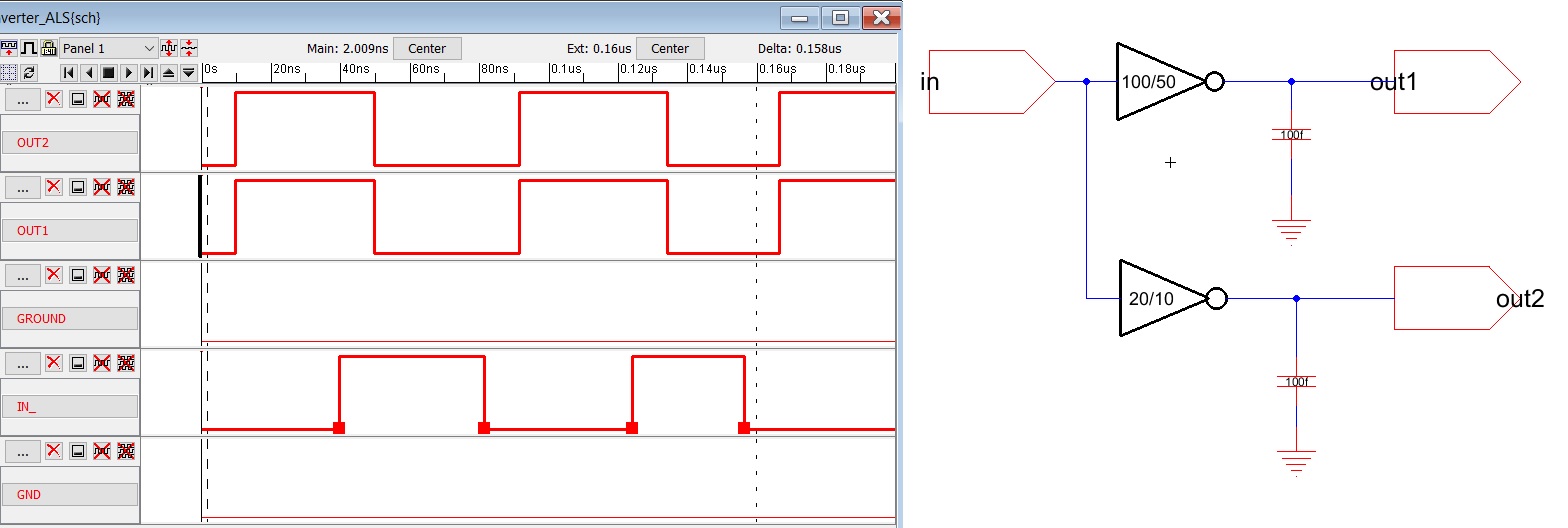

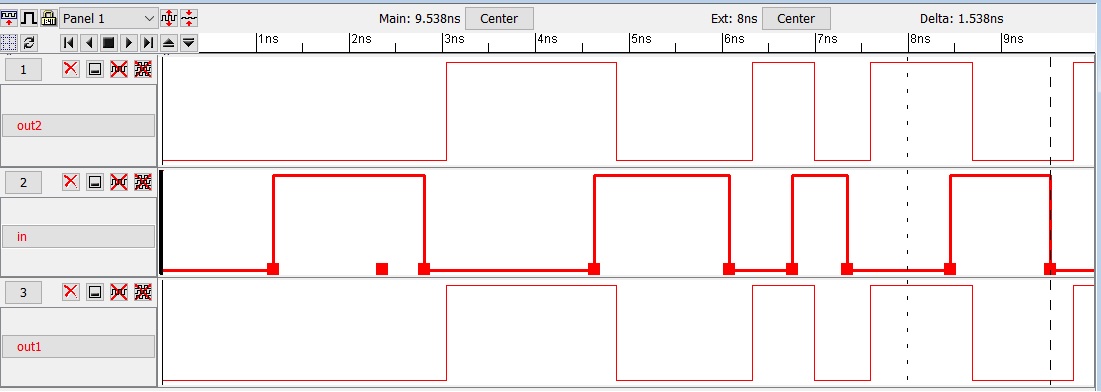

Figure 8. Simulation using the built-in ALS simulation tool.

Figure 9. Simulation using IRSIM simulation tool.

5. Discussion

For this lab, two different

inverters were made. In the first task the schematic and icon were

created for the 20/10 inverter. The task also asked for a transient

simulation with a pulse input; the results can be seen in figure 2 with

the simulation on top and the code used below. In task 2 the layout was

made using single components of the PMOS pieces that were widened to

the 20/10 specs. The resulting inverter was DRC clean. NCC clean, and

had 0 well errors. In task 3, the spice tools multiplier was used to

add an M=5 multiplier to the duplicated schematic cell. For the layout

portion of the task, different components were duplicated and

rearranged into the inverter seen in figure 5. This larger inverter

layout also passed the DRC, NCC, and well checks. The fourth task had

several simulations to show the driving capabilities of both inverters.

You can see that there's a issue in figure 6 of the 20/10 inverter

where it is attached to the 10pF capacitor and the blue V(out) signal

is not fully reaching 5V or 0V. In the same situation you can see that

the 100/50 inverter is able to handle the 10pF capacitor without the

above issue. For the last task two new simulation tools were used to

test the circuit shown on the right side of figure 8. Both simulations

showed slight delay times of the outputs. No major errors were

encountered in this lab and much was learned about the potential range

and uses of inverters. Overall a success!!