ENGR338 Lab Spring 2021

Lab 3: Layout the R-2R DAC

Name: Audra Benally

Email: albenally1@fortlewis.edu

1. Title: Layout the R-2R DAC

2. Introduction: The purpose of this lab was to practice the layout

portion of ElectricVLSI. We started a whole new R-2R ladder DAC from

the last lab. An important new process was implemented with the use of

subcells. The subcells are used to make larger circuit layouts easier

to debug and fix.

3. Materials and Methods:

Materials:

- Computer

- LTSpice Software

- ElectricVLSI Software

Methods:

For this lab,

we remade the R-2R ladder than we made in the last lab. A very

important technique using subcells were used for this lab. The subcells

are smaller repeating parts of the main circuit which are made and then

DRC checked for any issues. Once any issues are addressed, the smaller

parts are used to make the rest of the circuit. Since the big circuit

is made of DRC clean subcircuits, any problems that arise can be

pinpointed to the most recent part of the circuit made. This will help

when we start making huge circuits that have a lot of different parts.

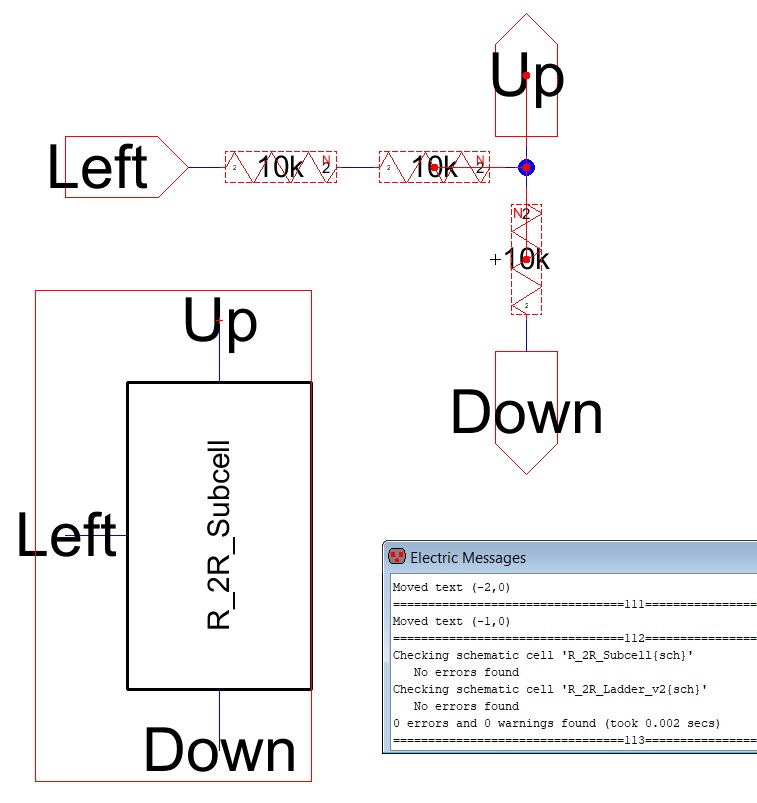

My subcircuits can be seen in figures 1 (schematic and icon) and 3

(layout). The subcell in figure 1 was used to make the R-2R ladder in

figure 2. The subcell in figure 3 was used to make the R-2R ladder in

figure 4. Because the subcells only contain repeating subcircuits, any

odd or unique parts are not included. So in figures 2 and 4, there is

an extra 10k resistor connected to the bottom of each ladder to

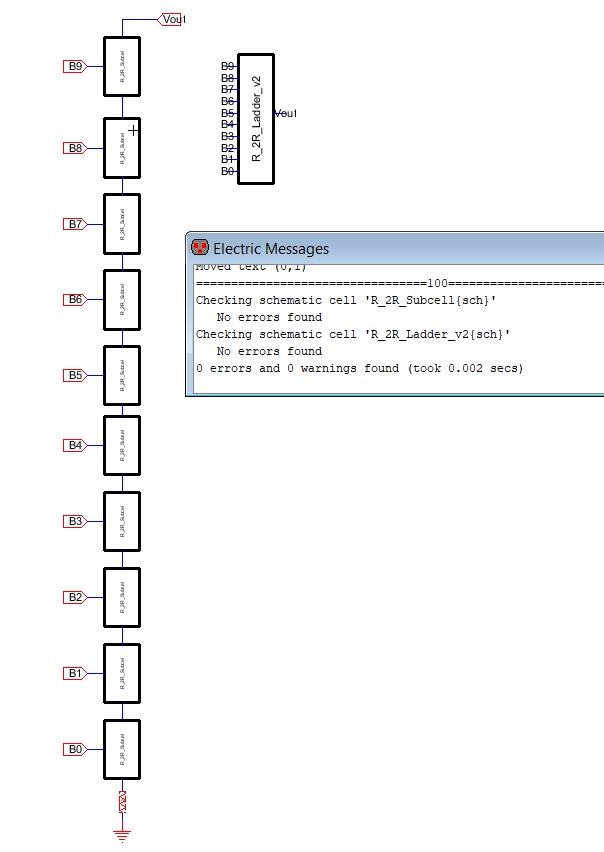

complete the R-2R ladder. Testing the circuit was a little tricky

because of the ideal ADC in the original simulation. So to test the

circuit I connected the new R-2R ladder DAC to the ideal ADC, as seen

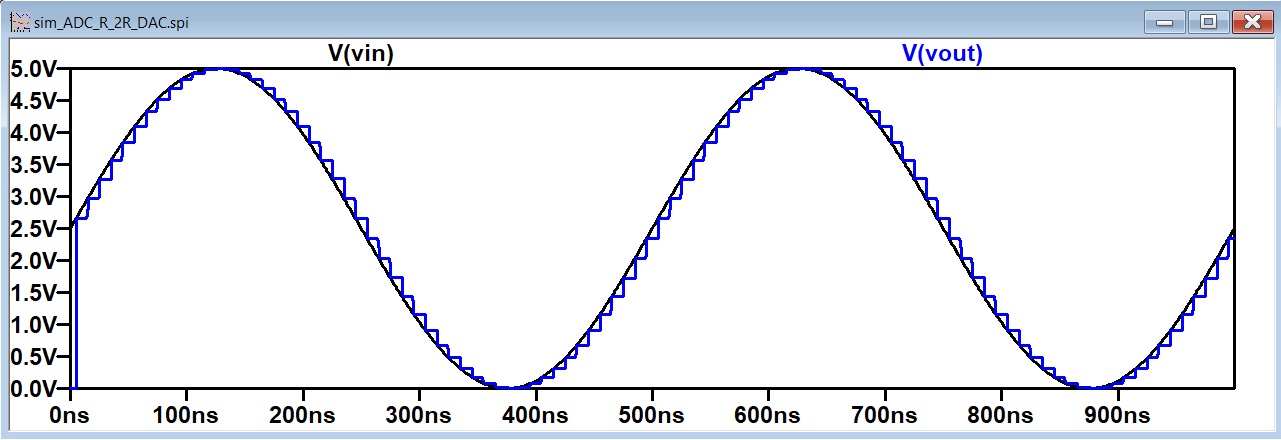

in figure 5, and ran the spice code. The simulation ran the way it was

supposed to, as seen in figure 6, so the layout portion of the R-2R

ladder DAC is likely correct and accurate.

4. Results:

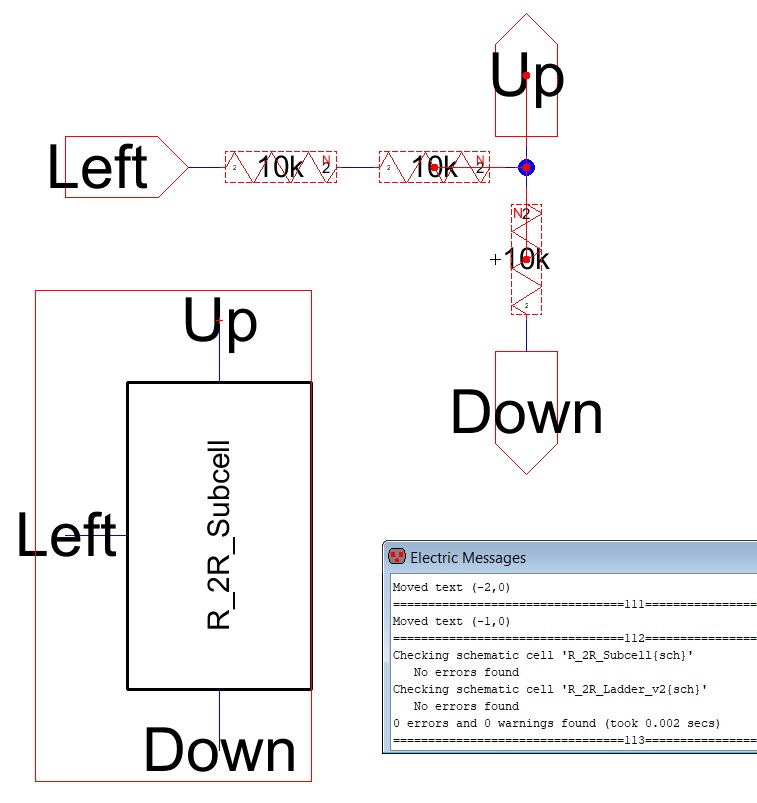

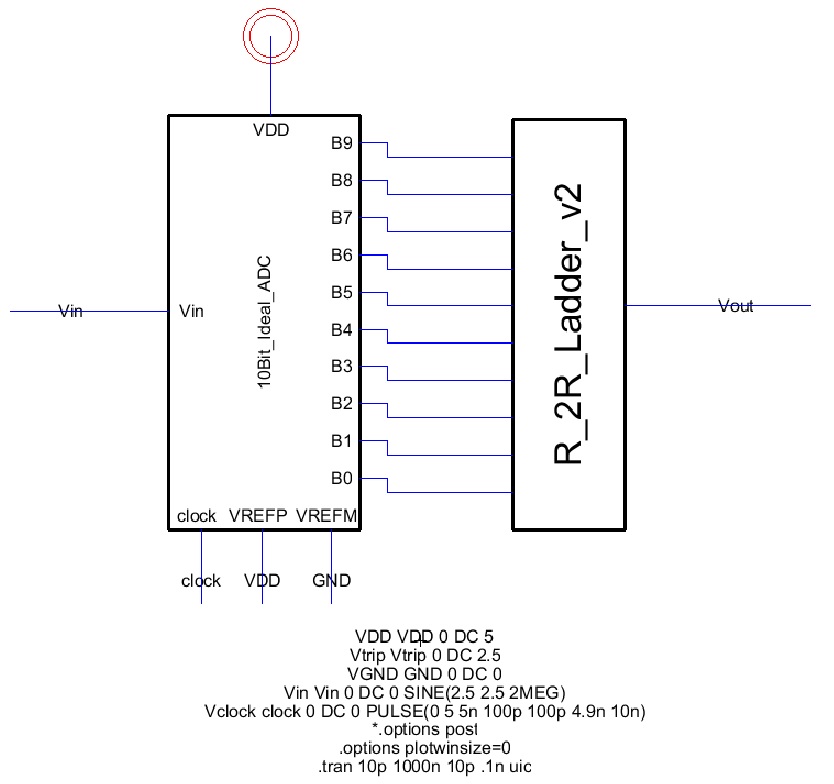

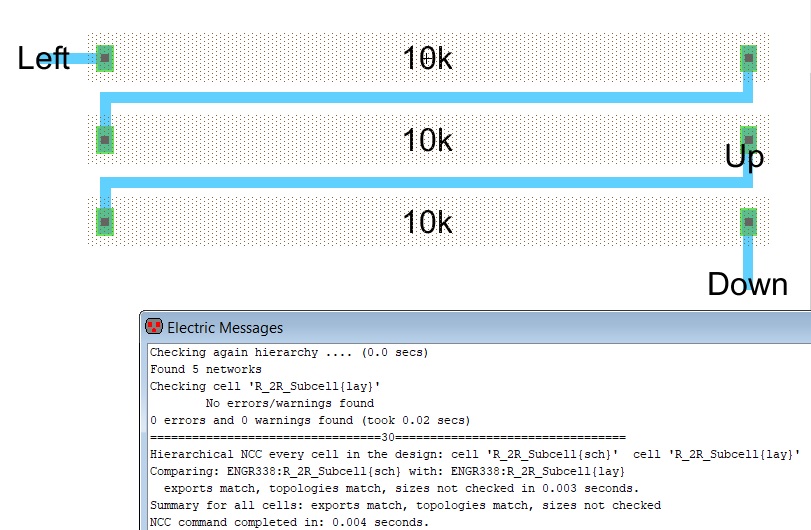

Figure 1.

Schematic and Icon of the R-2R subcell. The box shows the subcell is

DRC clean.

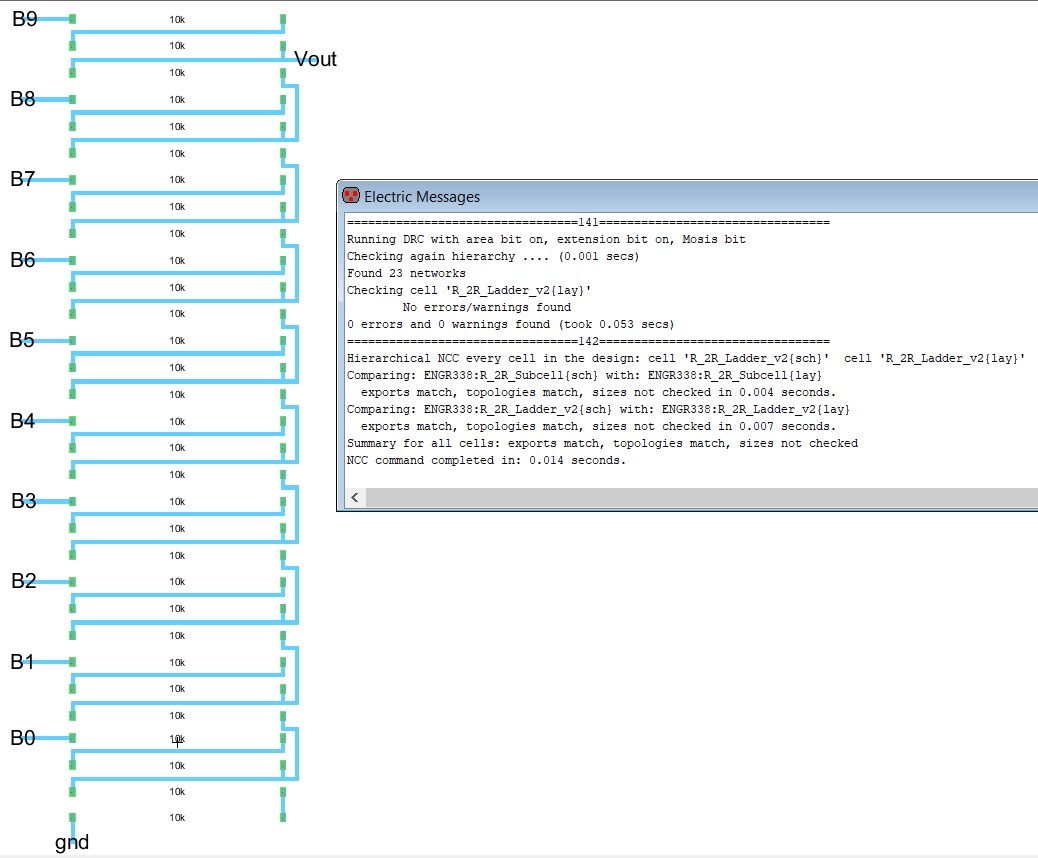

Figure 2.

R-2R ladder DAC version 2 with the subcells shown in Figure 1. The DAC

is DRC clean.

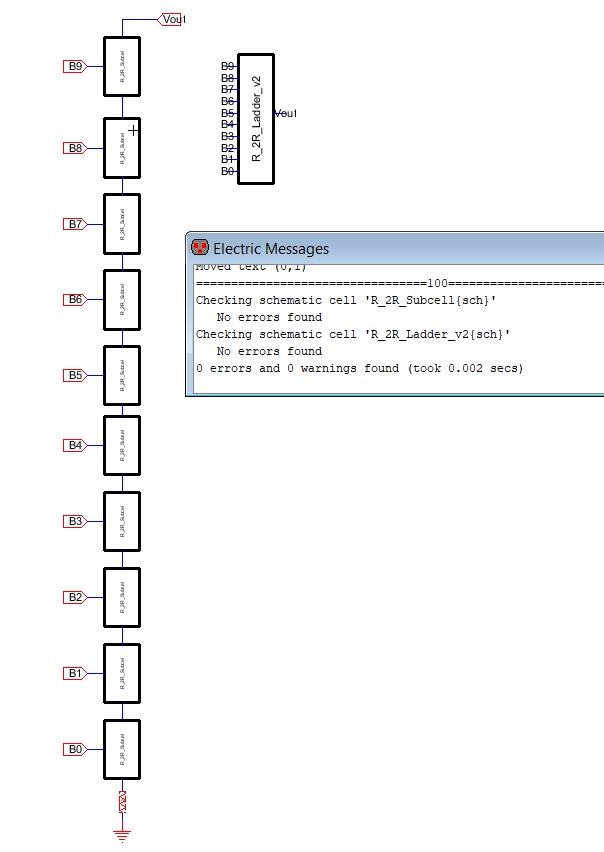

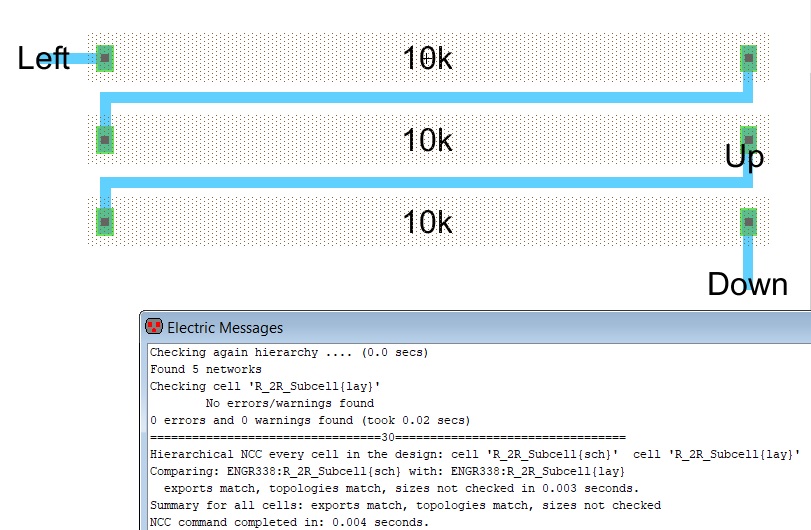

Figure 3. R-2R layout of the subcell. DRC and NCC show no errors.

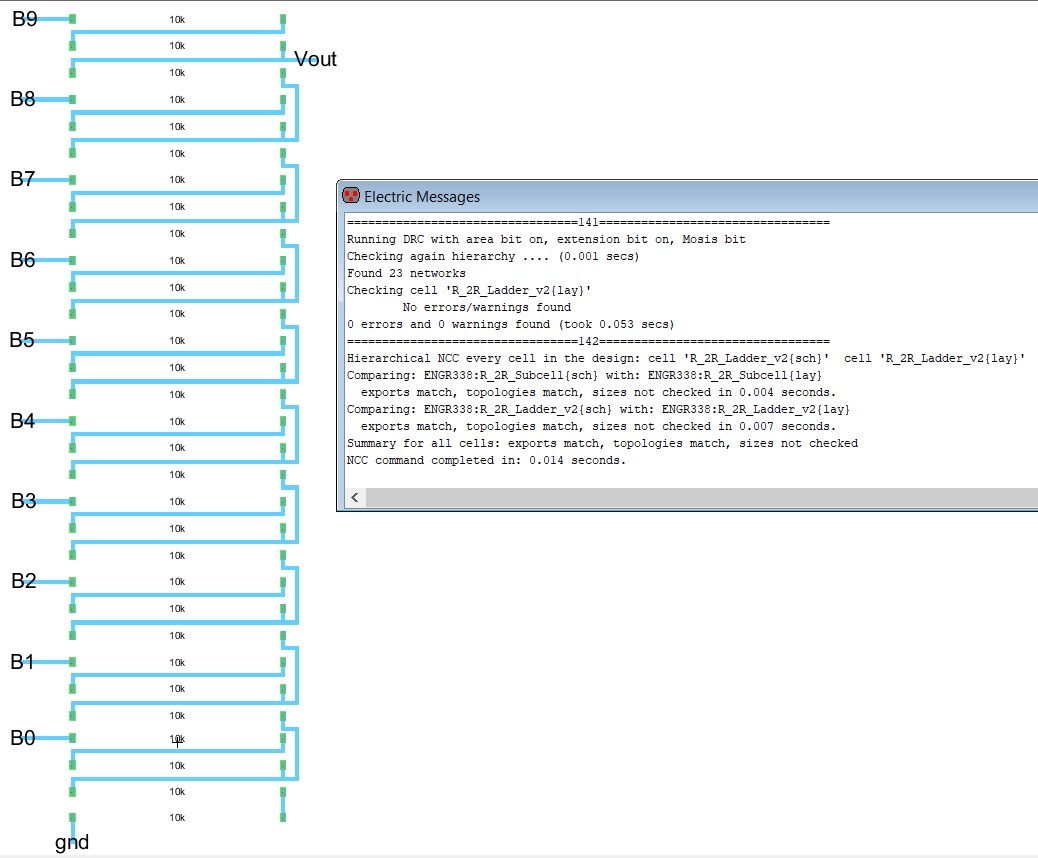

Figure 4.

R-2R ladder DAC v2 layout view made with the subcells shown in Figure 3. DRC and NCC tests show no errors.

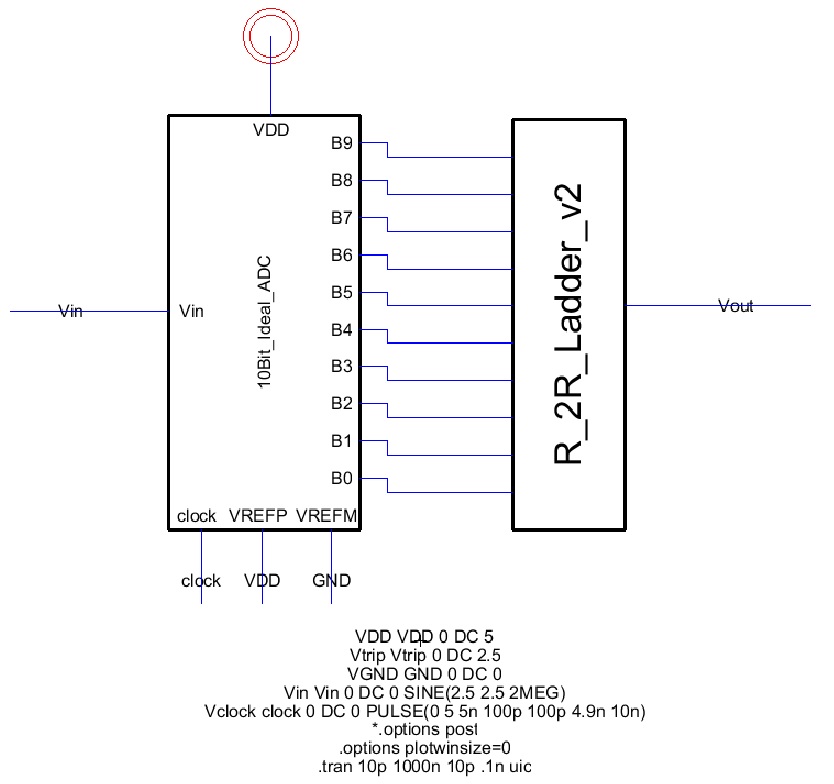

Figure 5.

R-2R Ladder DAC v2 connected to the ideal ADC for simulation.

Simulations results are shown in Figure 6.

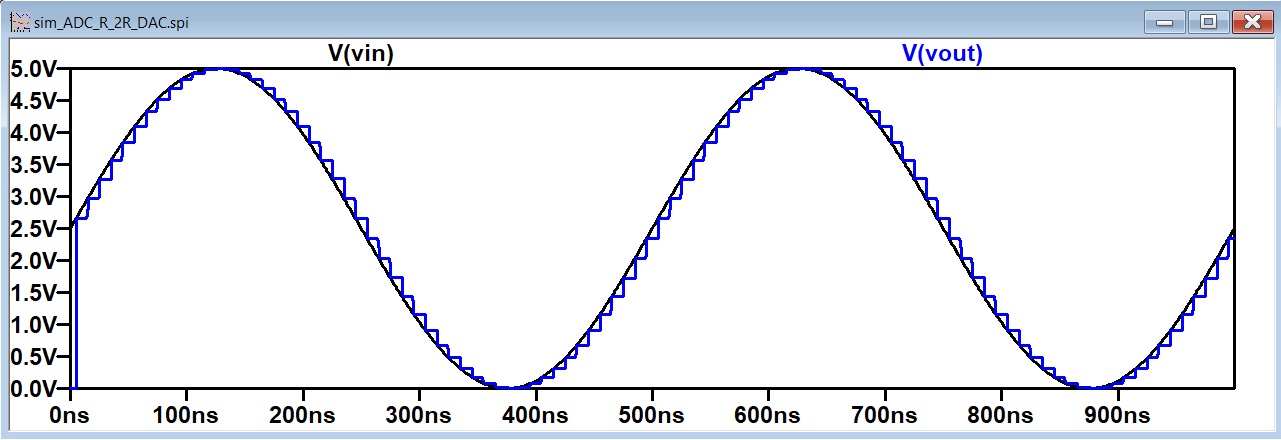

Figure 6.

Simulation results from the ideal ADC connected to the new R-2R ladder DAC.

5. Discussion

For this lab, the layout portion of the ElectricVLSI

software was reviewed and used to make another R-2R ladder DAC. The

schematic and icon view were remade using the subcell technique. All

portions of the scematic and icon were DRC appoved with no errors. The

schematic view of the R-2R ladder was made using the N-Well resistors.

I had a little trouble remembering which components to use but a quick

trip to the Tutorials on yilectronics.com cleared that right up. The

subcell was made first and was cleared with the DRC and NCC tests. Then

the rest of the ladder was made in the same manner as the icon and

schematic views. Because the ADC was ideal and could not be created in

layout view, the new R-2R DAC v2 icon was connected to the ideal ADC

and the spice code was simulated. Since the layout view was DRC and NCC

clean, the code working signified the layout was a success. My

simulation results can be seen in figure 6 and my connected ADC DAC

circuit can be seen in figure 5.