The experiment protocol is briefly described here. Some of the figures are attached.

It

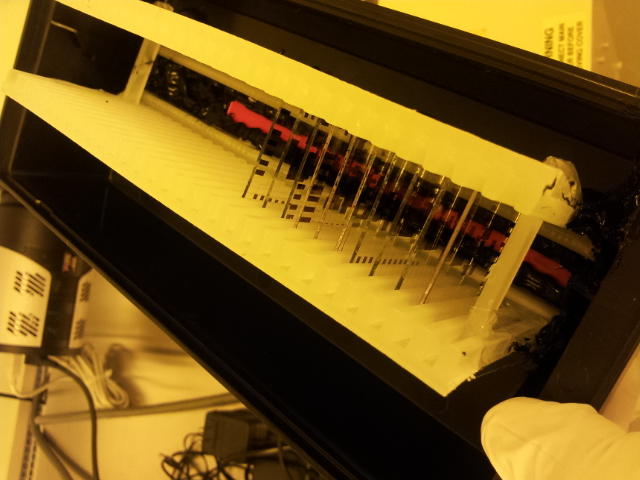

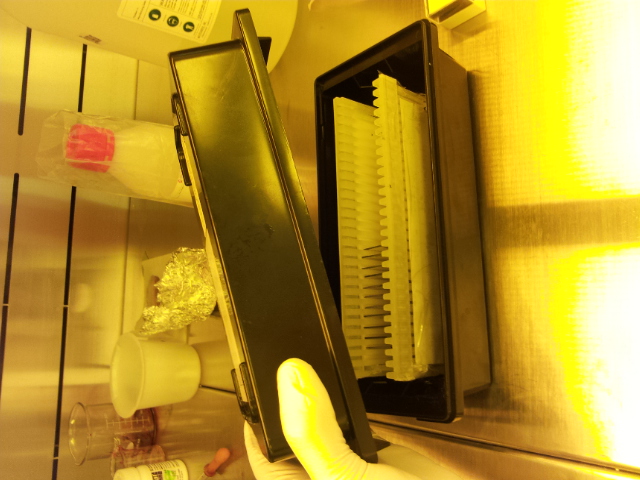

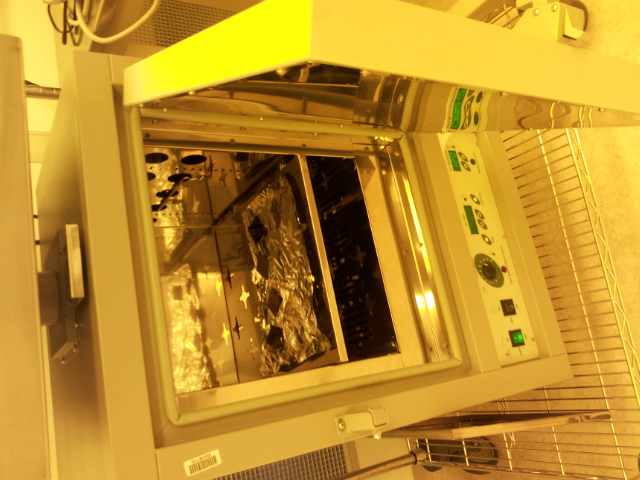

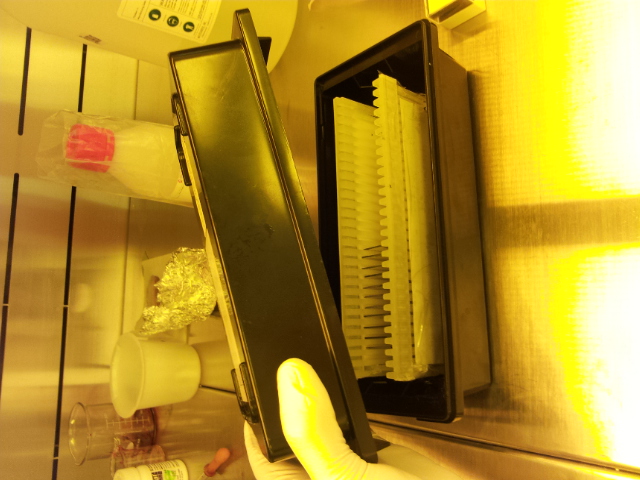

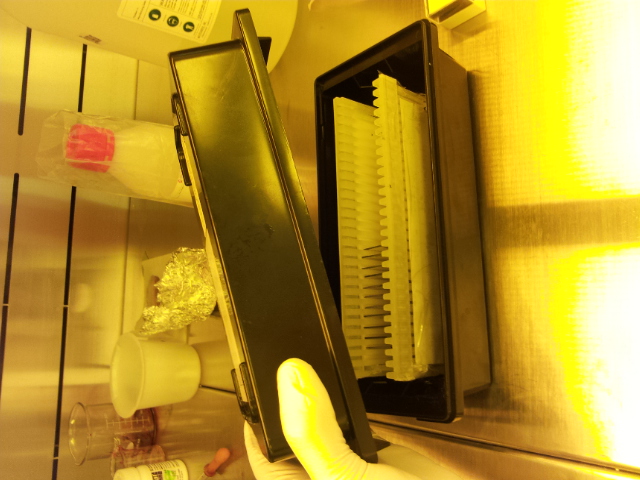

is fabricated in the cleanroom facility of Nevada Nanotechnology Center

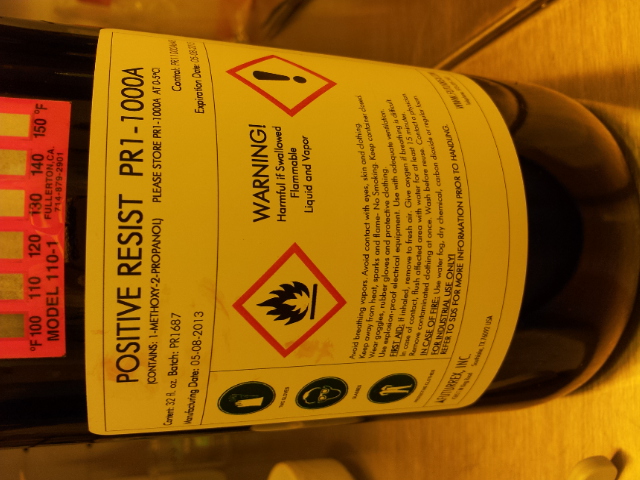

at University of Nevada, Las Vegas. The fabrication reagents includes

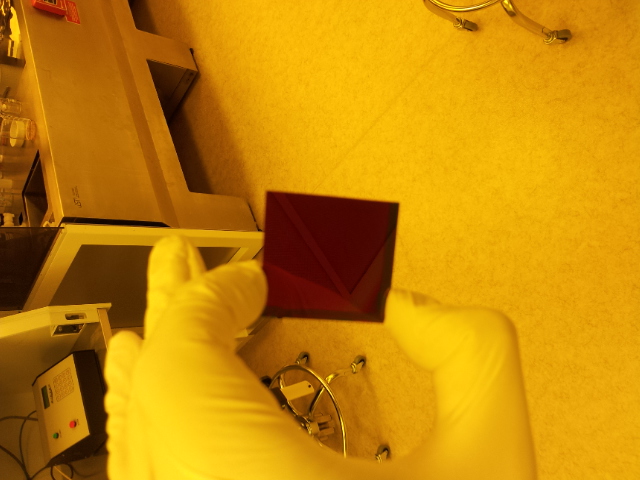

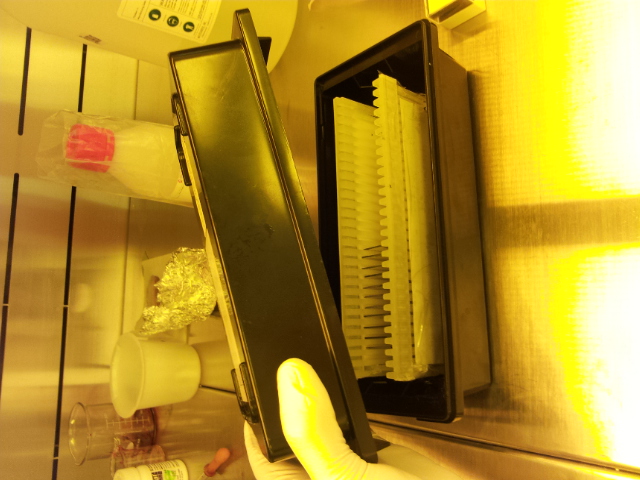

Schott Boro Float glass substrate with Chrome coated (100 nm)

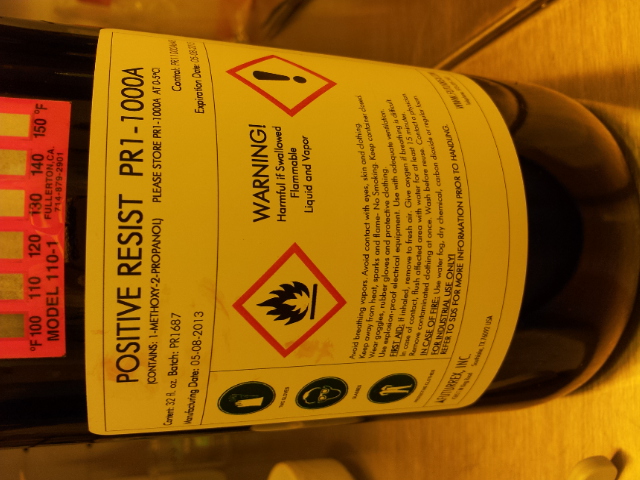

microfluidic blank slides (with positive photoresist coated, Telic,

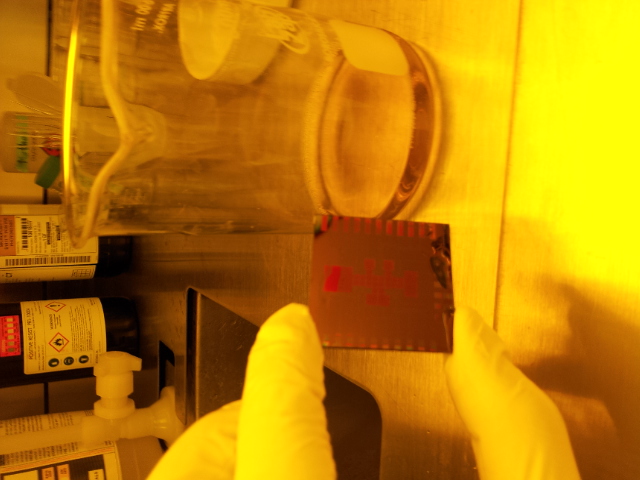

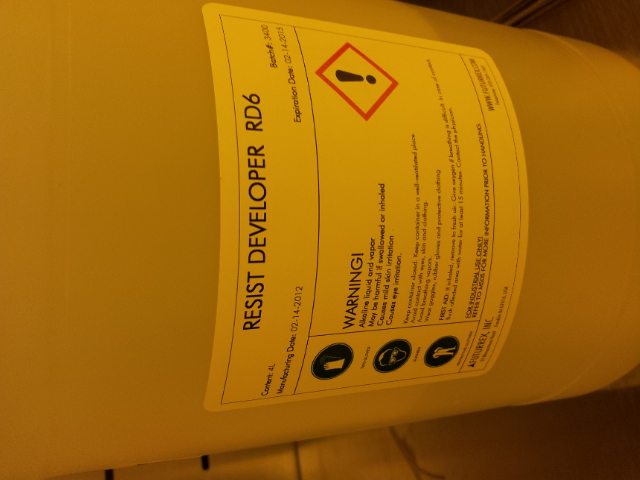

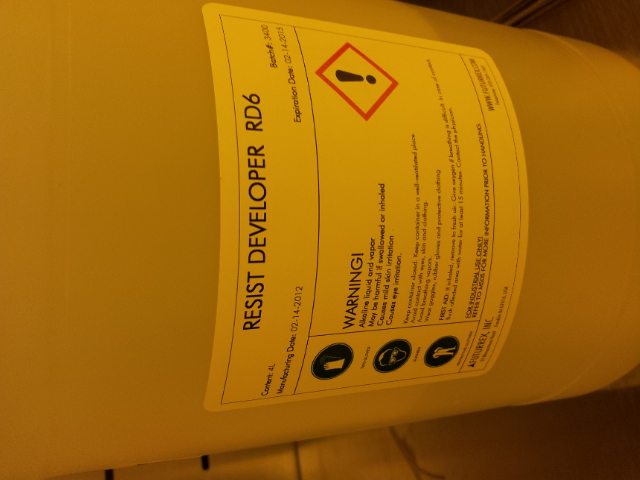

Valencia, CA, USA), photoresist developer RD6 (Futurrex, INC.,

Franklin, NJ, USA), Chromium etchant (Sigma-Aldrich, Co., MO, USA) and

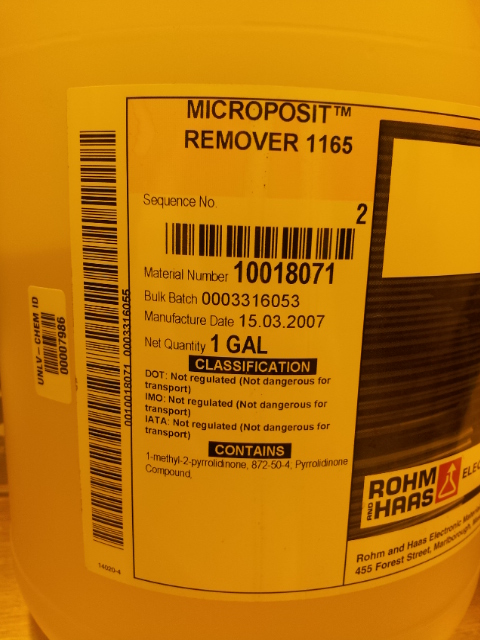

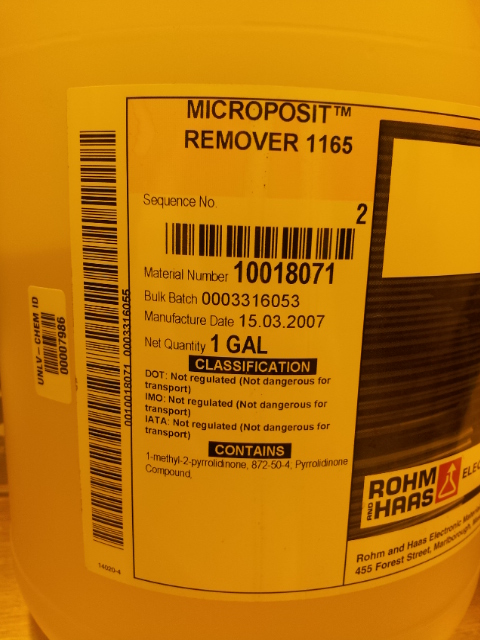

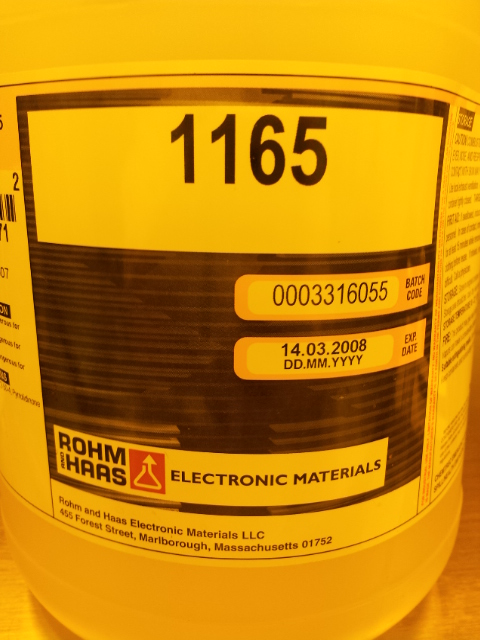

photoresist remover (Microposit Remover 1165, Rohm and Haas Electronic

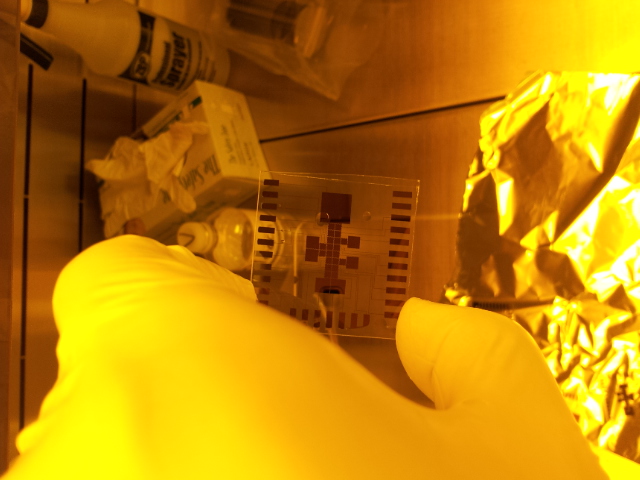

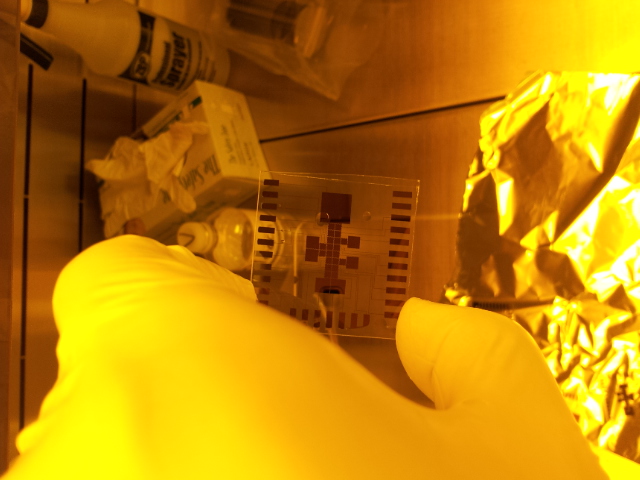

Materials LLC, MA, USA). Open source integrated circuit (IC) layout

tools Electric VLSI is used to pattern the mask of the electrode array.

GDSII output files from Electric VLSI were sent to Infinite Graphics

INC. (MN, USA) for plotting (25,000 dpi resolution) on a plastic

photolithography film.

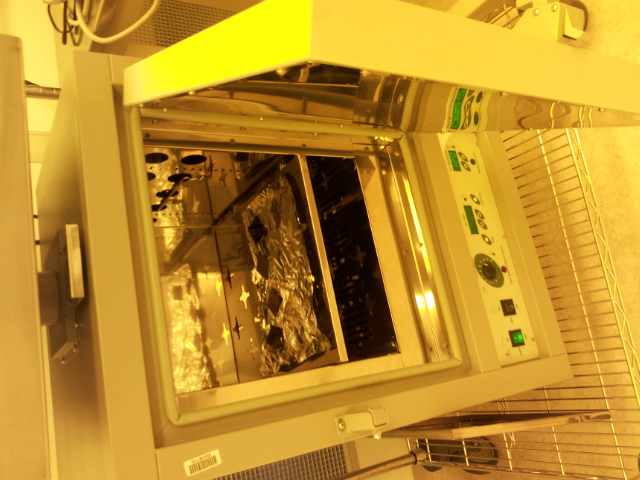

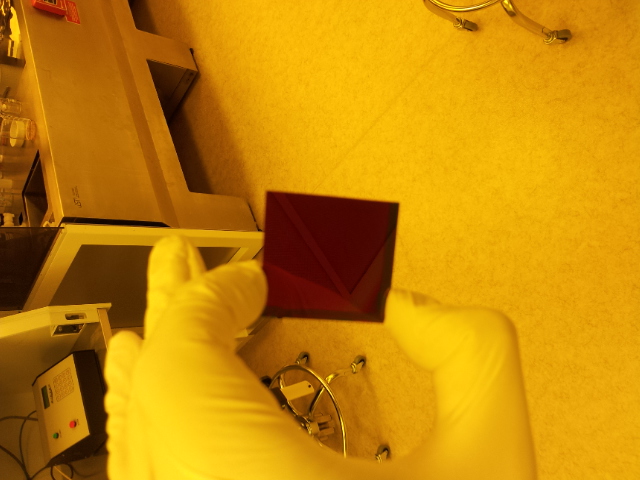

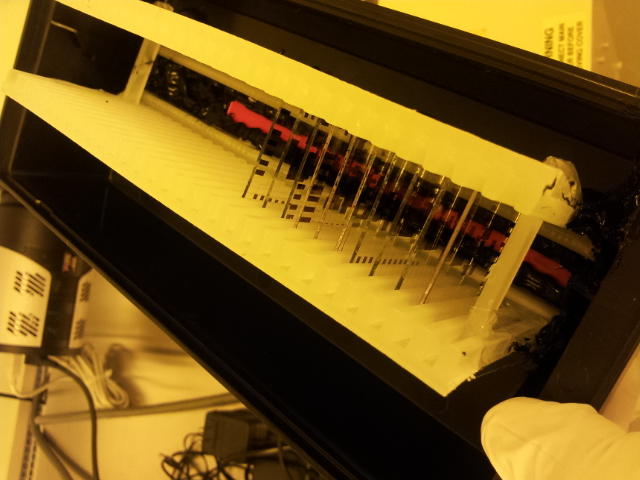

The substrates are covered by the patterned

photomask and exposed to a UV light source for 45 seconds and then

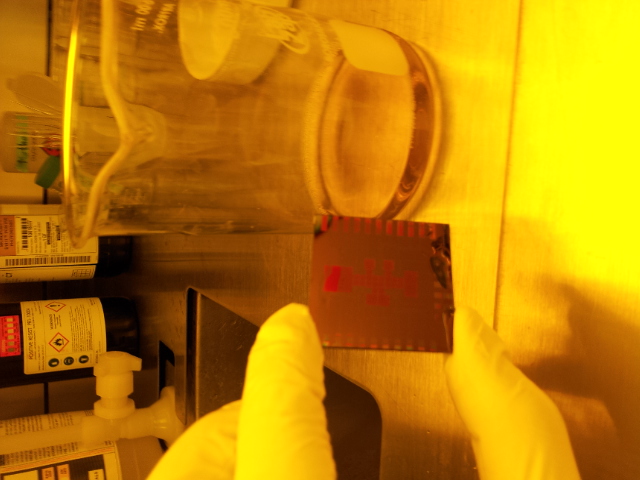

developed for 1 min in RD6. Substrates are then immersed in the

Chromium etchant for about 15-20 seconds. Then the substrates are

washed by DI water and dried out using nitrogen gas. The remaining

photoresist is removed by Microposit Remover 1165. If the remover

doesn't remove all of the photoresist Kimwipes (Uline, WI, USA) (wetted

by Microposit Remover or DI water) can be used to remove the remaining

photoresist.