Week 13-14

Project

ESP32

Introduction

For our final project we were given the

opportunity to either

fabricate the IoT Temperature Monitor that we designed in

Homework 2 or the ESP32 module that was designed in Homework 3.

I chose to fabricate the ESP32 module as I enjoyed learning and

designing the module in Homework 3. In order to creat the

module, we needed to design the module using EAGLE, have the PCB

fabricated through PCBWay, solder all the necessary parts to the

PCB board, and finally test the module.

Design

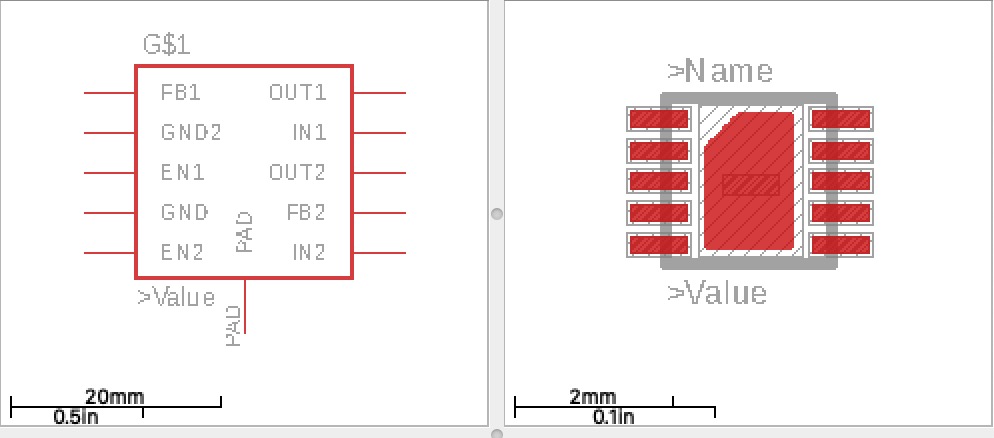

To

design the PCB needed to create the ESP32 module we needed to

use EAGLE. The first thing we needed to do was to find the right

low-dropout (LDO) voltage regulator to use for our module. The

Texas Instrument TLV7510 voltage regulator was selected as it

best fit the specifications for our module. In EAGLE we needed

to create the TLV7510 component as shown in Figure 1. Once we

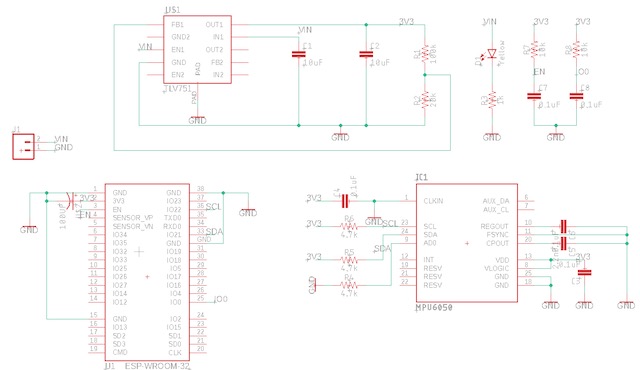

had all the required parts to design our module in EAGLE we

created a schematic to connect the components as shown in Figure

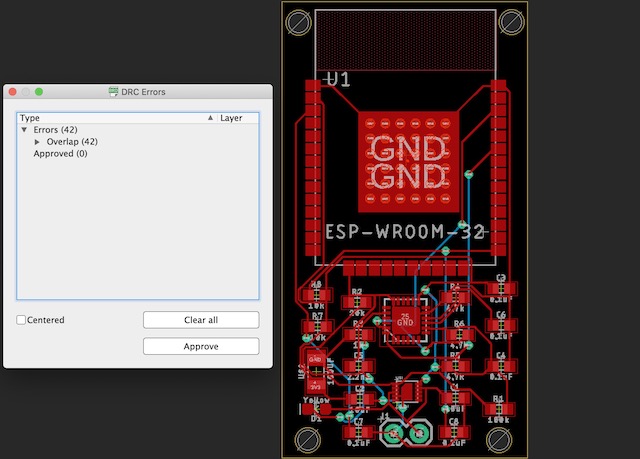

2. After the schematic was completed, the BRD layout could be

created where we could place the components on the PCB as

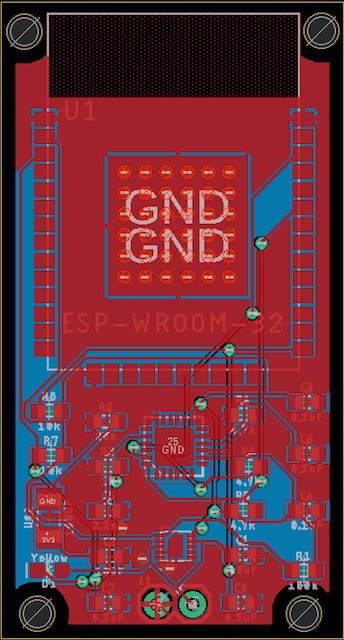

desired and route the PCB, which is shown in Figure 3. Then when

the board was routed we could finally pour the copper to finish

the board and we would have a finished product that would be

ready for fabrication as shown in Figure 4.

Fabrication

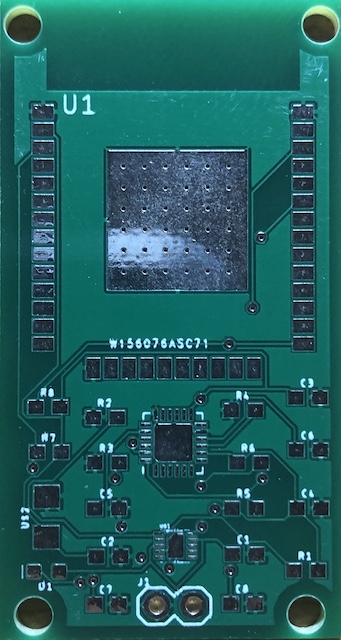

Once

we had the PCB created we created the gerber files that would be

sent to PCBWay so they could fabricate the board. Before sending

the gerber files, we needed to use an online PCB viewer like PCB

Investigator to check to make sure the board was designed

correctly as shown in Figure 5. Once we confirmed everything

looked correct we sent Dr. Li our gerber files so he could order

the PCB from PCBWay that way we can get a fabricated PCB like

the one shown in Figure 6.

Solder

Testing

MASTER CODE:

#include "FS.h"

#include "SD.h"

#include "SPI.h"

#include<esp_now.h>

#include<WiFi.h>

#include<Wire.h>

const int MPU=0x68;//Device address

int16_t AccX, AccY, AccZ;

uint8_t broadcastAddress[] = {0x24, 0x62, 0xAB,

0xF9, 0x24, 0xC8}; // Receiver's mac address

typedef struct struct_message{

int16_t AccX, AccY, AccZ;

} struct_message;

struct_message MPU6050Readings;

void setup(){

Wire.begin(); //To redefine the

I2C pins: Wire.begin(SDA,SCL) or Wire.begin(SDA,

SCL, Bus_Speed).

Wire.beginTransmission(MPU);

Wire.write(0x6B);//Wake up the

MPU chip

Wire.write(0x00);

Wire.endTransmission(true);

Wire.beginTransmission(MPU);

Wire.write(0x1C);//Talk to the

ACCEL_CONFIG register (1C hex)

Wire.write(0x08);//Set the

register bits as 00001000 (+/- 4g full scale

range)

Wire.endTransmission(true);

Serial.begin(115200); // It's

fine to use a higher speed other than 9600 but

remember to change the rate in your serial monitor

WiFi.mode(WIFI_STA);

if (esp_now_init() != ESP_OK) {

Serial.println("Error initializing ESP-NOW");

return;

}

esp_now_peer_info_t peerInfo;

memcpy(peerInfo.peer_addr,

broadcastAddress, 6);

peerInfo.channel = 0;

peerInfo.encrypt = false;

if

(esp_now_add_peer(&peerInfo) != ESP_OK){

Serial.println("Failed to add peer");

return;

}

}

void loop(){

accRead();

MPU6050Readings.AccX=AccX;

MPU6050Readings.AccY=AccY;

MPU6050Readings.AccZ=AccZ;

esp_err_t result =

esp_now_send(broadcastAddress, (uint8_t *)

&MPU6050Readings, sizeof(MPU6050Readings));

//Send the data. &MPU6050Readings is just a

8-bit character pointer to store the data

}

void accRead(){ // read the MPU data to ESP32

Wire.beginTransmission(MPU);

Wire.write(0x3B);//Start with

register 0x3B

Wire.endTransmission(false);

Wire.requestFrom(MPU,6,true);//

Read 6 registers total

AccX=Wire.read()<<8 |

Wire.read();

AccY=Wire.read()<<8 |

Wire.read();

AccZ=Wire.read()<<8 |

Wire.read();

Wire.endTransmission(true);

}

SLAVE CODE:

#include "FS.h"

#include "SD.h"

#include "SPI.h"

#include<esp_now.h>

#include<WiFi.h>

#include<Wire.h>

int16_t incomingAccX, incomingAccY, incomingAccZ;

const int MPU=0x68;//Device address

typedef struct struct_message{

int16_t AccX, AccY, AccZ;

} struct_message;

struct_message incomingReadings;

void OnDataRecv(const uint8_t * mac, const uint8_t

*incomingData, int len) {

memcpy(&incomingReadings, incomingData,

sizeof(incomingReadings));

incomingAccX=incomingReadings.AccX;

incomingAccY=incomingReadings.AccY;

incomingAccZ=incomingReadings.AccZ;

}

void setup(){

Serial.begin(115200);

WiFi.mode(WIFI_STA);

if (esp_now_init() != ESP_OK) {

Serial.println("Error initializing ESP-NOW");

return;

}

esp_now_register_recv_cb(OnDataRecv);

}

void loop(){

Serial.print(incomingAccX);

Serial.print(" ");

Serial.print(incomingAccY);

Serial.print("

");

Serial.println(incomingAccZ);

}

Discussion