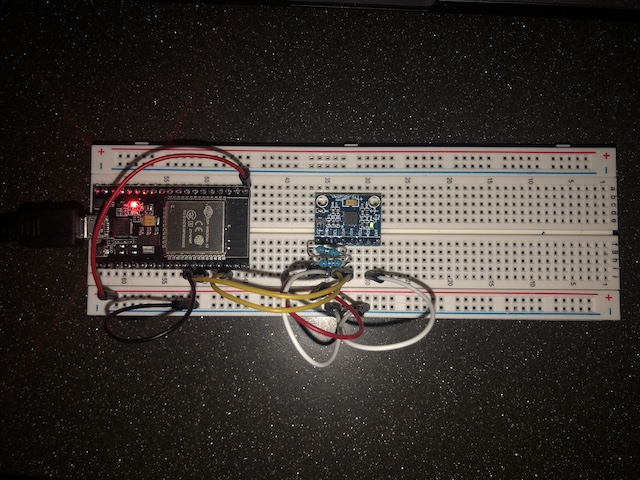

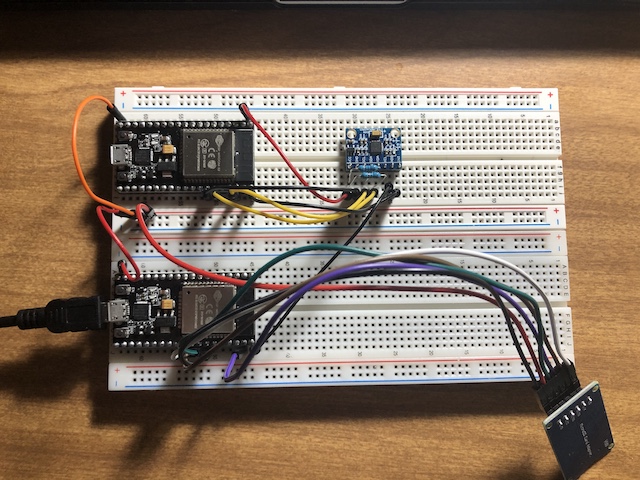

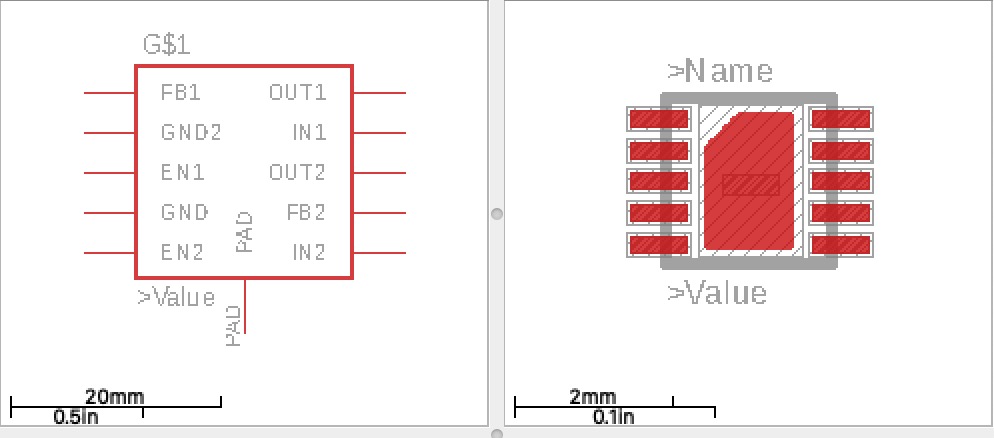

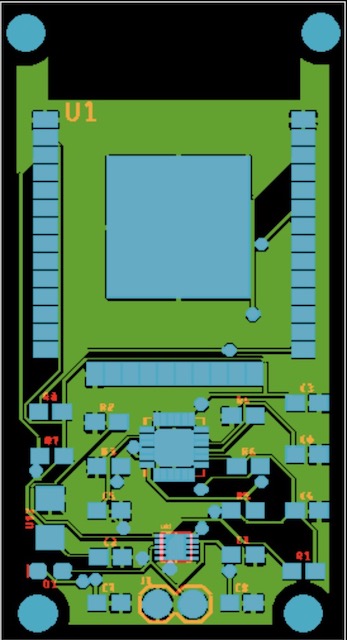

Figure 1. Layout for connecting MPU6050 to ESP32.

Week 8-11

Advanced IoT Devices (ESP 32)

Introduction

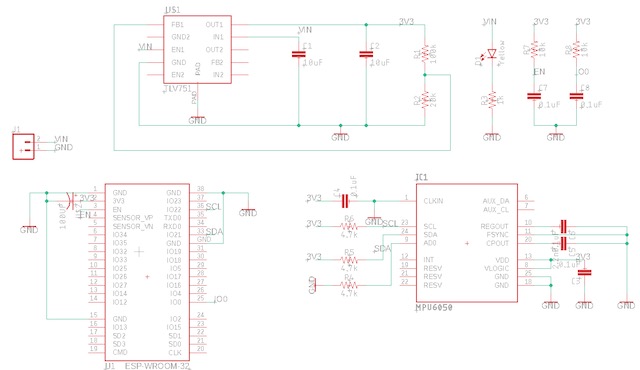

In

this lecture, we learned about the ESP32 module, MPU6050 module,

and Micro SD card adapter. The goal was to become more familiar

with the ESP32 module. We used the I2C communication protocol

extensively to communicate between module. We further refined our

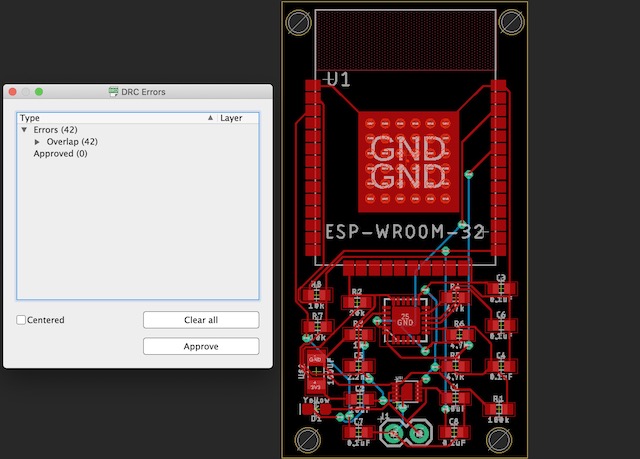

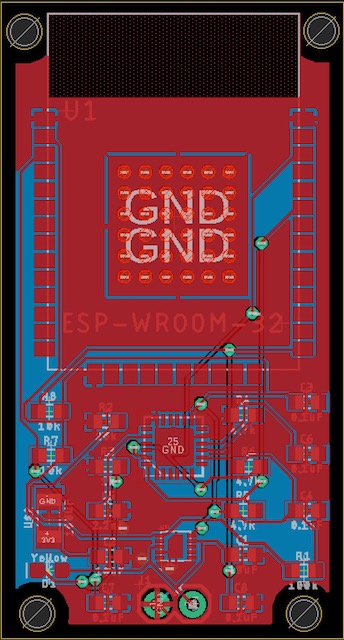

skills using EAGLE to create a PCB that incorporated the ESP32 and

MPU6050 modules.

Task 1

For Task 1, we needed to

install esp32 through the board manager. Once it was installed we

had to configure it in Arduino by

choosing the

'ESP32 Dev Module' board, the '11520 upload speed', the 'AVRISP

mkII' programmer. After it was configured, we were given a

simple blinking program to run and the results are shown in the

video below.

Task 2

For Task 2, we were the

connection layout for the ESP32 and MPU6050 and had to make the

connections as shown in Figure 1. Once the MPU6050 was connected

to the ESP32 we were given some code to run that would acquire

data from the MPU and plot the data in the Serial Plotter as shown

in the video below.

Task 3

For Task 3, we were presented with a

variation of different codes that had flaws in them that would

produce the incorrect plot. The fifth piece of code that was

presented gave us the correct plot as can be seen in the video

below.

Task 4

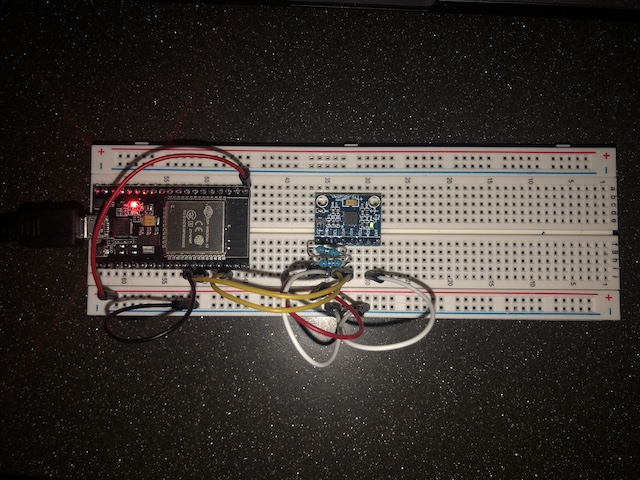

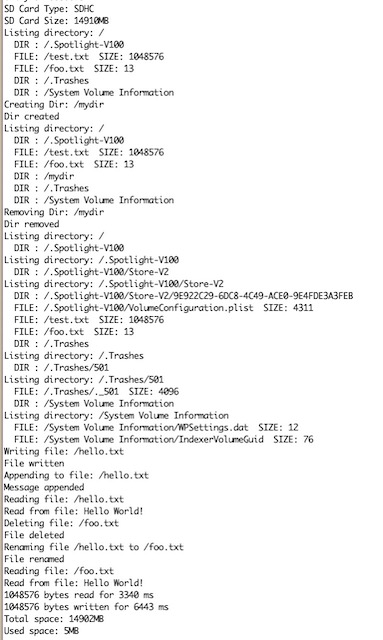

For Task

4, we added a micro SD card adapter so that we could

store the data collected on an SD card, as shown in

Figure 2. We were given some code that

let us know

that our SD card was communicating with your ESP board

successfully. The result of the SD card communicating

with the ESP board can be seen below in Figure 3./Part%201/Task_5_Setup.jpg)

Figure 2. ESP and SD card being connected together.

Task 5

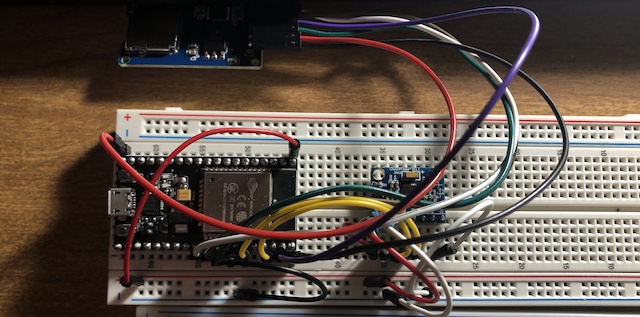

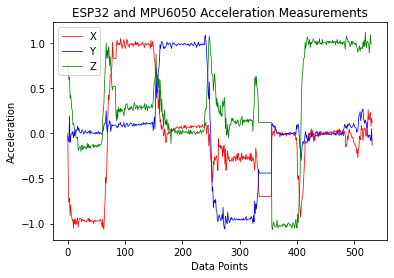

For Task 5, we connected

the ESP, MPU, and SD card together so that the

data read from the MPU could be stored on the SD

card, the setup is shown in Figure 4. We then

had to modify the code given to receive all

AccX, AccY, and AccZ data in separate data files

'AccX.txt', 'AccY.txt', and 'AccZ.txt' and then

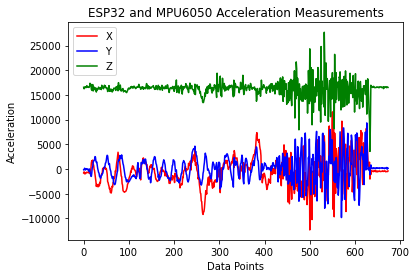

plot the data using python as shown in Figure 5.

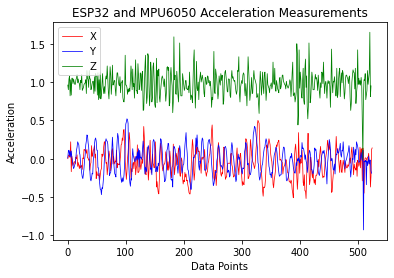

Task 6

For Task 6, we had to change

the data type of AccX, AccY, and AccZ to

'float' and use the intermediate int16_t

variables AccX_temp, AccY_temp, and

AccZ_temp to store the 16-bit

accelleration data from the MPU sensor.

Then we used python to plot the data acquired as shown in Figure

6.

Task 7

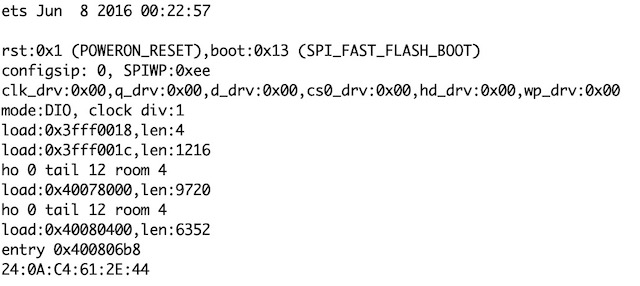

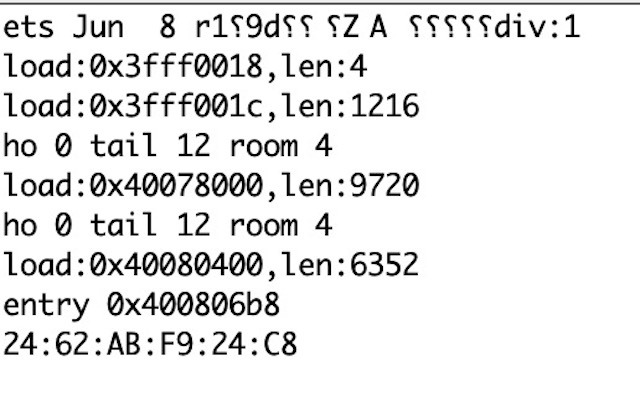

For Task

7, we connected two ESP module

together, as shown in Figure 7,

but we need to get the MAC

address of each module, which

can be seen in Figure 8 and

Figure 9. We were given

code that needed to be uploaded

to the

master and the slave

respectively, then connect the

USB cable to the slave. Once the

code had been uploaded to both

ESPs then we could open the

serial plotter in Arduino and it

would show the data being

plotted in realtime as shown in

the video below.

/Part%201/Task_7_Setup.jpg)

Figure 7. Connecting two ESP

modules and MPU6050.

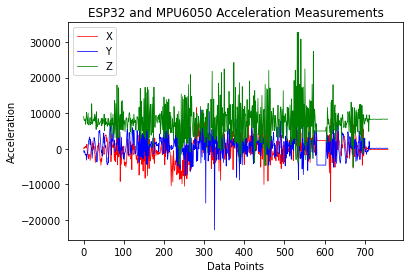

Task 8

For Task 8,

we needed to add the

SD card so that we

could store the data

the was transferred

from the master to the

slave from the MPU.

The setup is shown in

the Figure 10. Then we

had

to

alter

the code given to

receive the

acceleration data

from the master

wirelessly by the

slave and store the

data to the SD card.

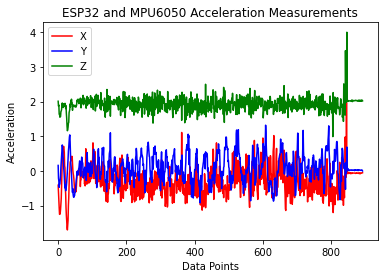

After we plotted the

stored data using

python as shown in

Figure

11 and Figure 12.

Task 9

For

Task 9, we

needed to

clean up the

code for the

master and

slave, which

are both given

below. Then we

used the

cleaned up

code to

acquire data

to store on

the SD card

and used

python to plot

the data as

shown in

Figure 13.

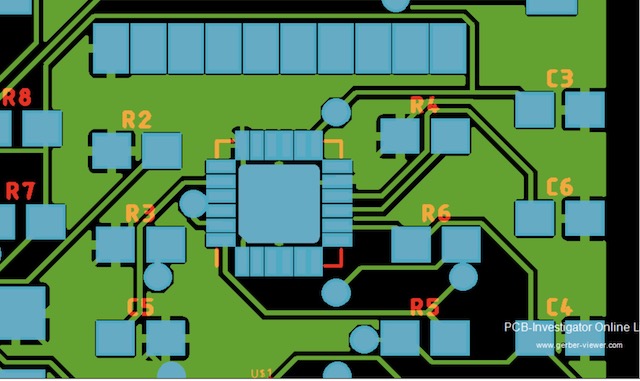

Discussion

By

completing these tasks it gave me a better understanding of the

ESP32 module, MPU6050 module, and the I2C communication protocol.

I was able to refine my programming skills by seeing different

ways that code could be implemented. I was also to get more

experience with EAGLE as we created a module that used the ESP32

and MPU6050 modules, which Dr. Li is sending to PCBWay to get

fabricated as that will be our final project. This was a good

hands on learning experience.