CE 432 Fall 2021

HW 4: 3D Printing

Taylor Nakai

tsnakai@fortlewis.edu

Introduction:

In homework, we had to follow Noah's 3D Printing Tutorial that

was provided. The tutorial had us go through the process of getting a

simple component printed using AutoCAD SOLIDWORKS, Ultimaker Cura, and

the 3D printer in BH602. This homework was necessary as it allowed us

to gain experience with the 3D printing process to prepare us for

upcoming Robotics II projects and other tasks that require 3D printed

components. The first step required the component to be designed using

the AutoCAD SOLIDWORKS software. The second step required the Ultimaker

Cura software to modify the 3D printing settings, the orientation of

the component, and converting the STL file that SOLIDWORKS provides

into G-code. The final step required us to load the G-code to the 3D

printer via microSD and print the component.

Step 1: AutoCAD SOLIDWORKS

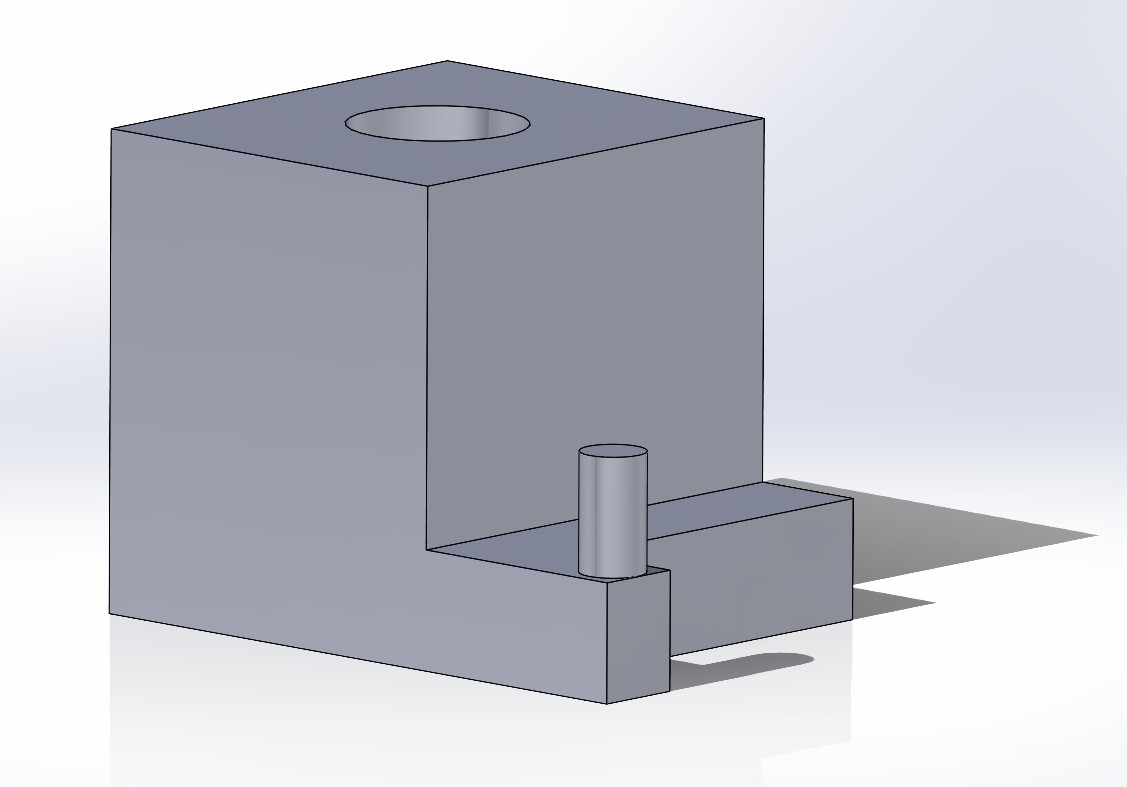

In step 1, the

component to be designed using the AutoCAD SOLIDWORKS software. To

begin we needed to select that we were creating a new part. We need to

configure the dimension so they are in millimeters before we start

sketching and extruding the component. We can finally start sketching,

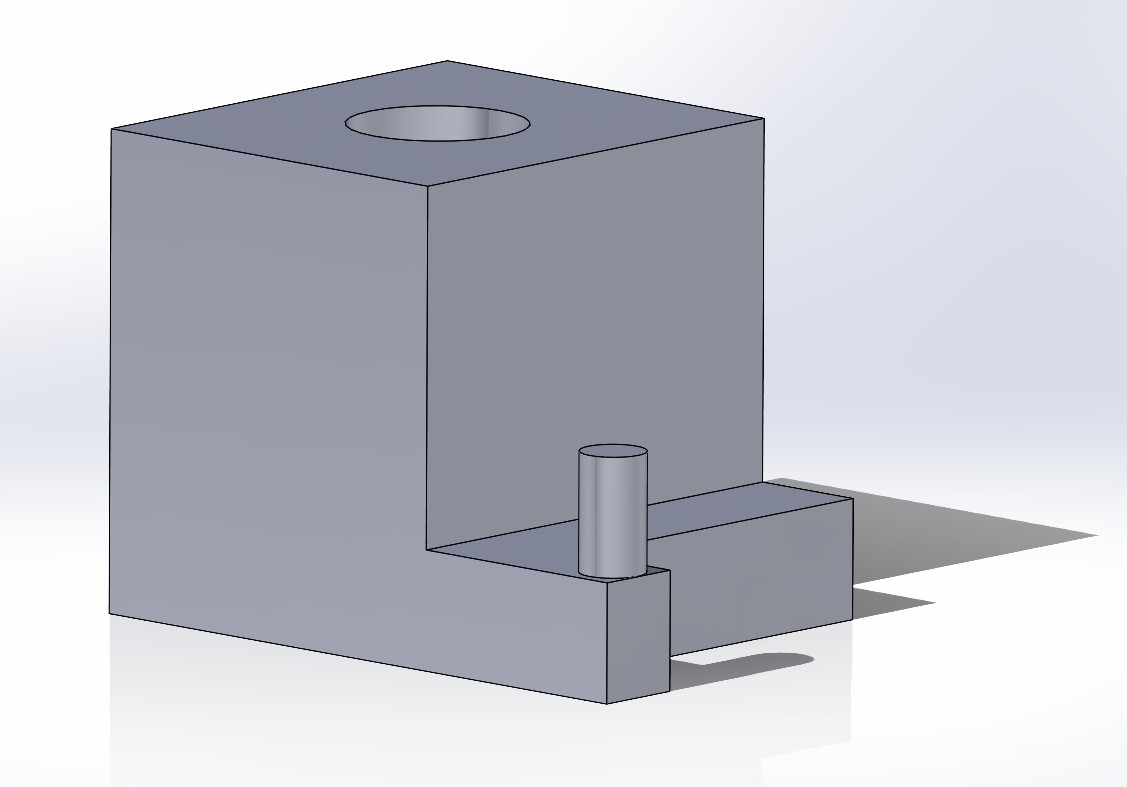

dimensioning, and extruding the component. After this is all done the

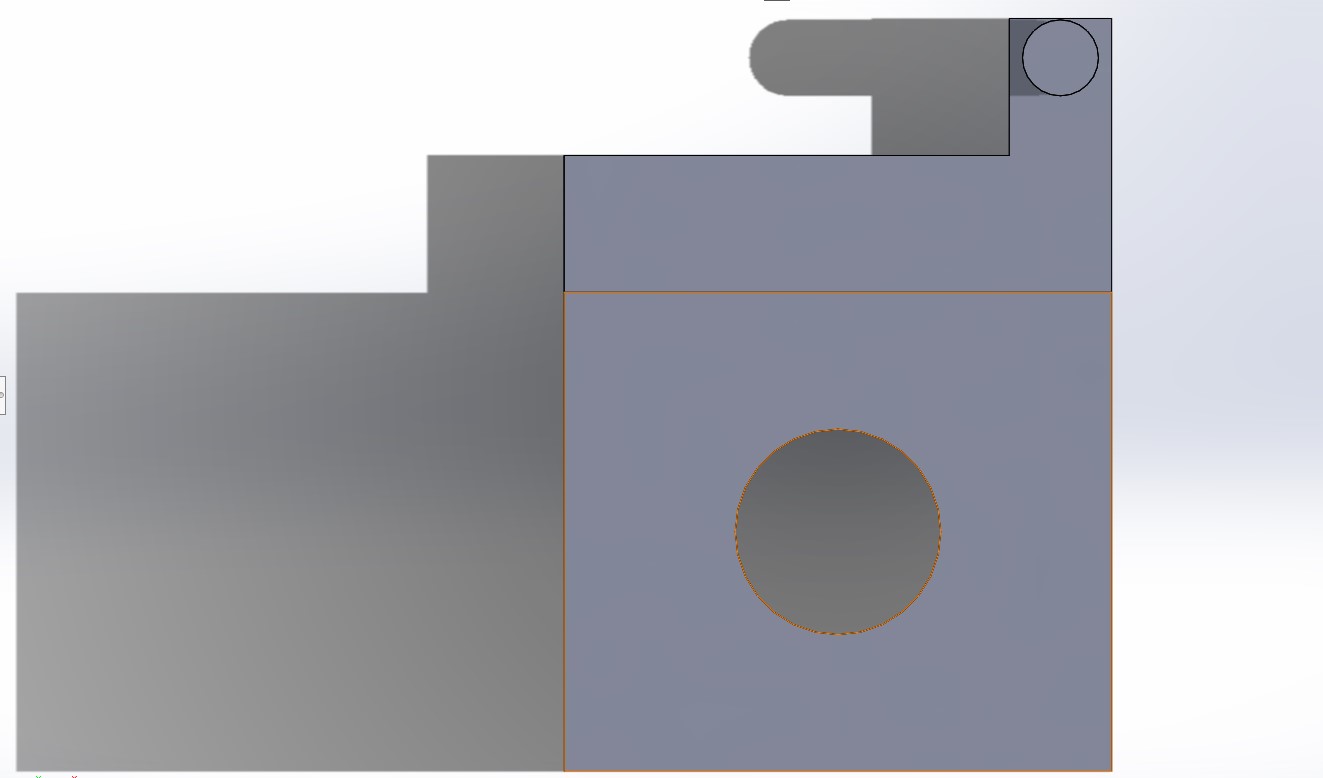

final design of the component is shown in Figure 1 and Figure 2.

Figure 1. Final design of component after all the sketching, dimensioning, and extruding has been completed in SOLIDWORKS.

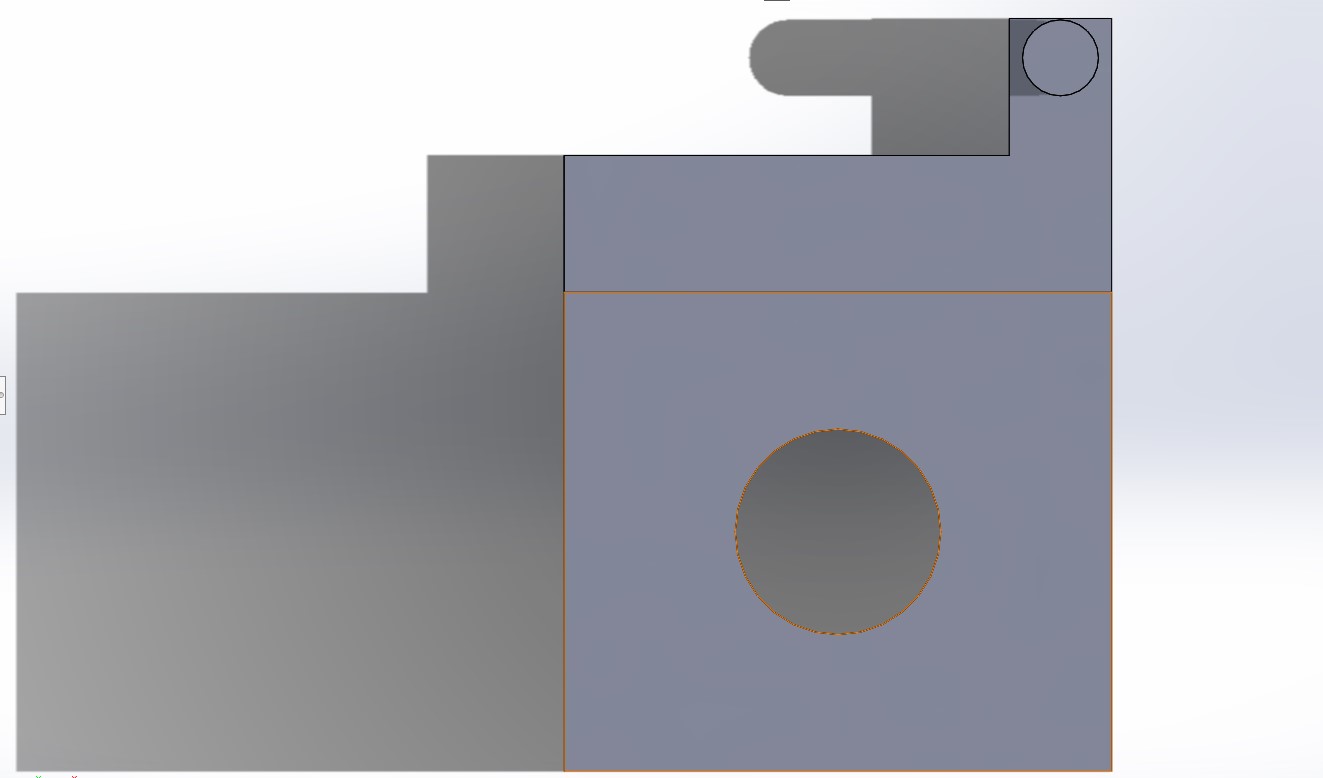

Figure 2. Top view of component showing through hole.

Step 2: Ultimaker Cura

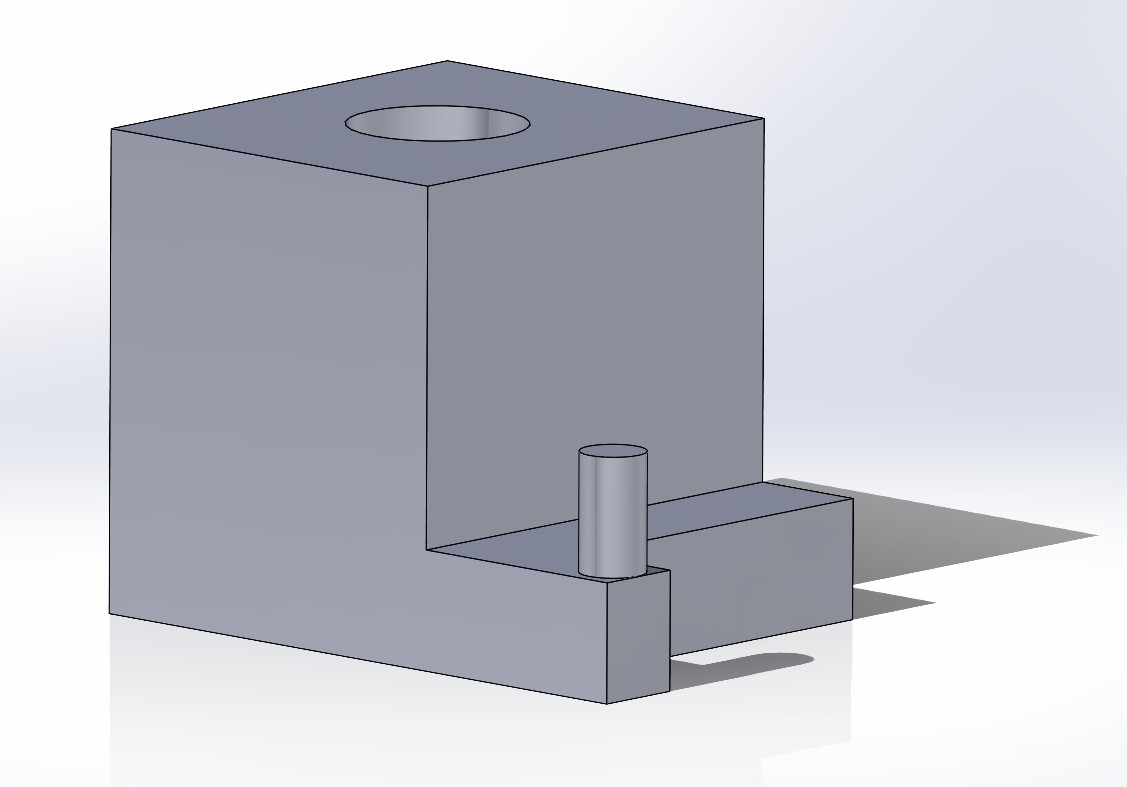

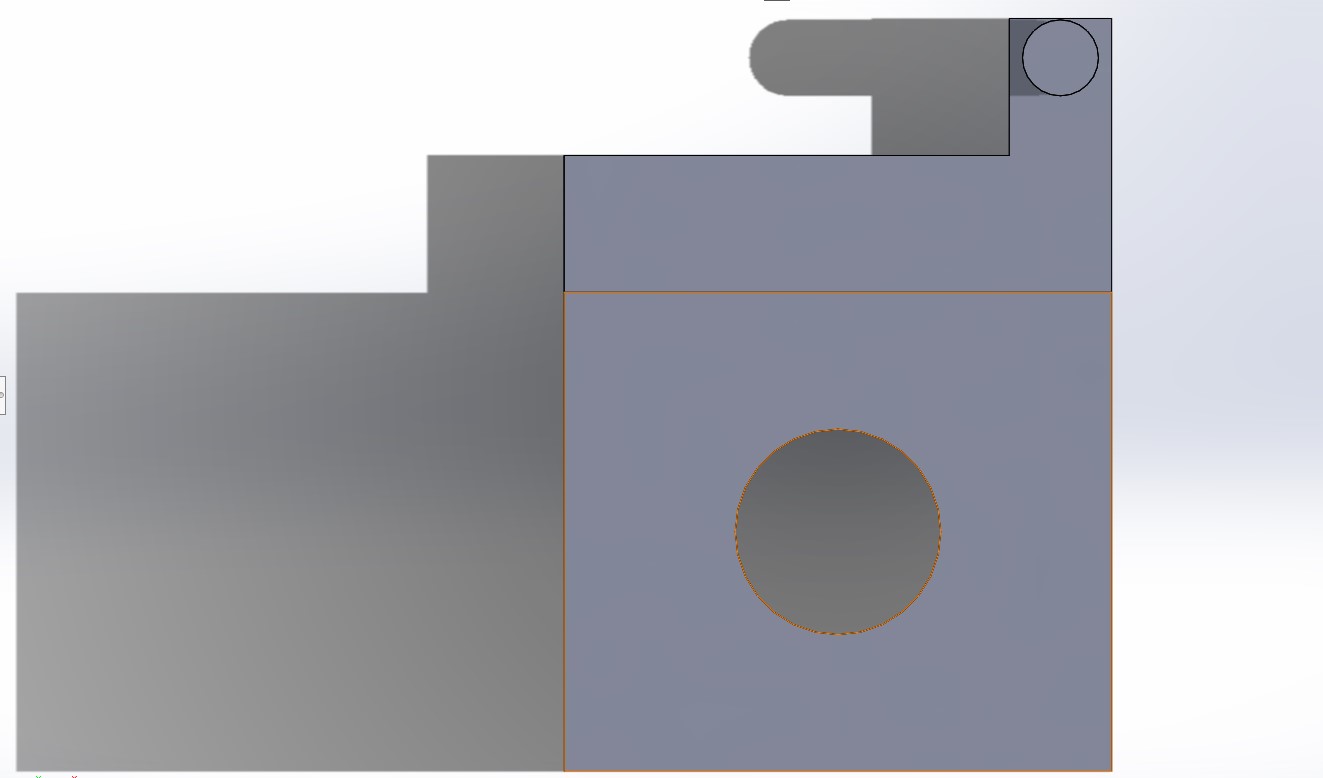

In step 2, required

the Ultimaker Cura software to modify the 3D printing settings, the

orientation of the component, and converting the STL file that

SOLIDWORKS provides into G-code. We need to also indicate the type of

printer that is being used to create the component. The component need

to be positioned in the lower left corner of the printer's surface, as

shown in Figure 3. Once we are happy with the position, orientation,

and settings we can finally slice the file so that it can be converted

to G-code, to be saved to a microSD card.

Figure 3. Showing the placement and orientation of the component in Ultimaker Cura.

Step 3: Printing Component Using 3D Printer

The

final step required us to load the G-code to the 3D printer via microSD

and print the component. Once we get the G-code from Cura, we are able

to load that to the 3D printer and then select that file to be printed.

Once that had been done, we just needed to sit back and let the printer

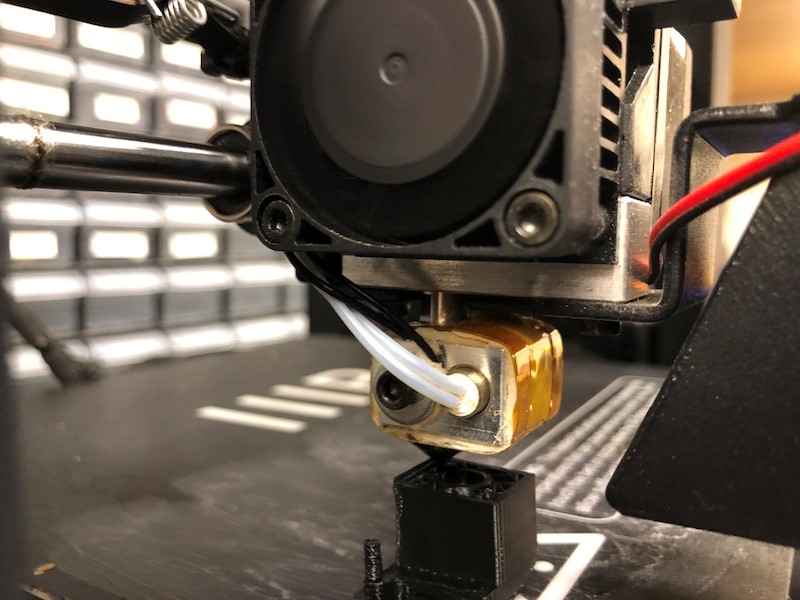

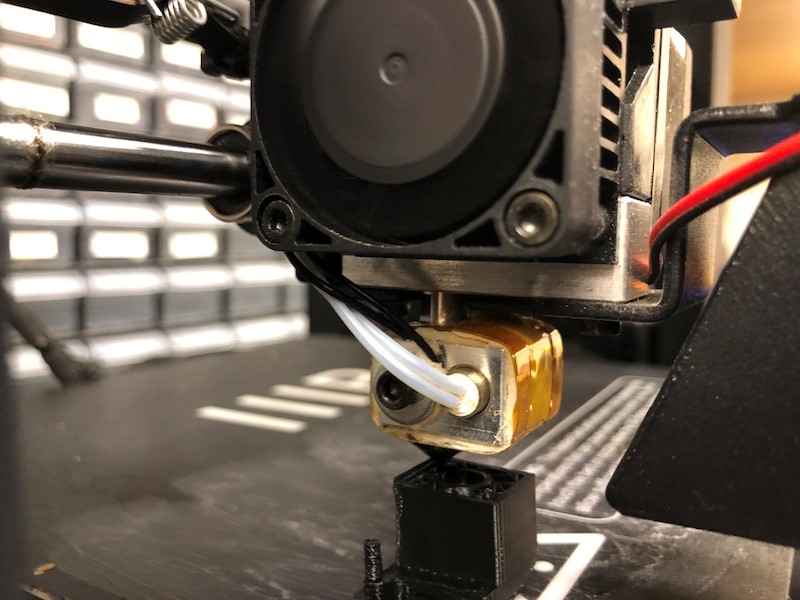

do its job. In Figure 4, it shows the 3D printer hard at work printing

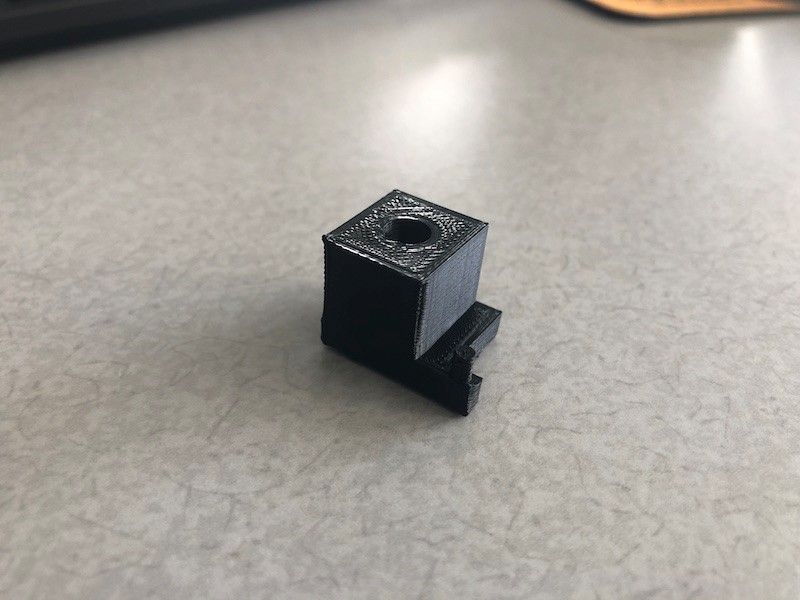

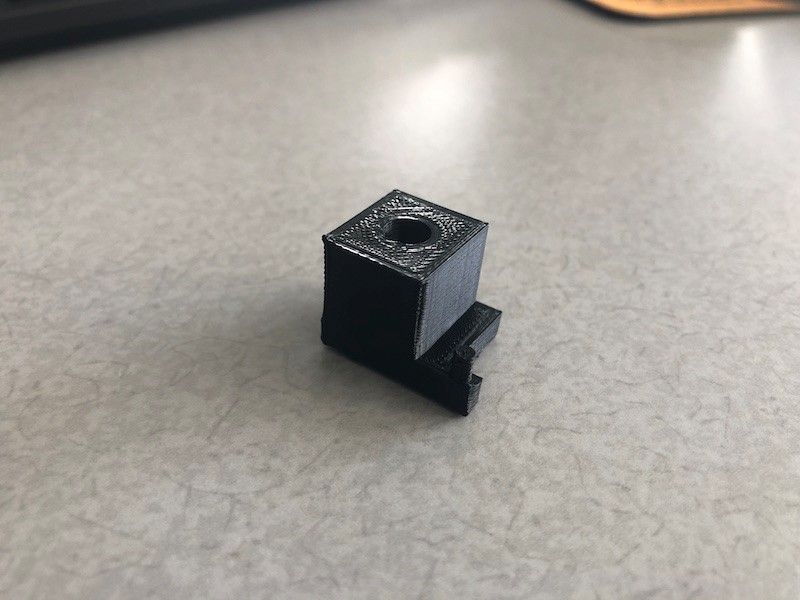

my component. The printed component is shown in F igure 5.

Figure 4. Showing the 3D printer hard at work printing my component.

Figure 5. Showing the completed 3D print of the component.

Discussion:

By

completing this Noah's tutorial, I feel more comfortable using

SOLIDWORKS, Cura, and the 3D printer. I think I would be able to

successfully create a component using the process that we learned. I

did run into an error when printing my part as the print stopped

midway, and this was due to the microSD not having enough free space.

To fix this problem, I just uploaded my code to a blank microSD card

and that seemed to fix the problem. I think that using the 3D printer

was very cool and I will most likely be using it in the future to print

different components as it was an easy process.