CE351 Lab 2020 Fall

Power Supply and DC Regulators on a PCB for MCUs

Name: Audra Benally

Email: albenally1@fortlewis.edu

1. Title: Power Supply and DC Regulators on a PCB for MCUs

2. Introduction:

In this lab, a functioning power supply board will

be designed to use with future MCUs. The program being used will be

Eagle PCB. Personal libraries and devices will also be made to

accomodate for parts not included in the SparkFun library. Gerber files

will then be made and sent to PCBWay for fabrication. Once the boards

came in, the components were soldered and assembled. The resulting

board was tested for accuracy.

3. Materials and Methods:

Materials:

- Computer with Eagle PCB

- Step by step tutorials from yilectronics.com

- Calculator

- Soldering iron

- Multimeter

- Flux

- Solder

- Board components: capacitors, inductors, diodes, chips, etc...

Methods:

For this lab, a step by step tutorial was followed

to create a power supply board. The first circuit was constructed with

devices from the SparkFun library. The second and third circuits needed

specific devices that were not included in the given libraries. Several

capacitors, inductors, a diode, and two 5-pin LM2596 devices were

created from the datasheets of each specific component. Once the parts

were built, the last two circuits were constructed. The completed

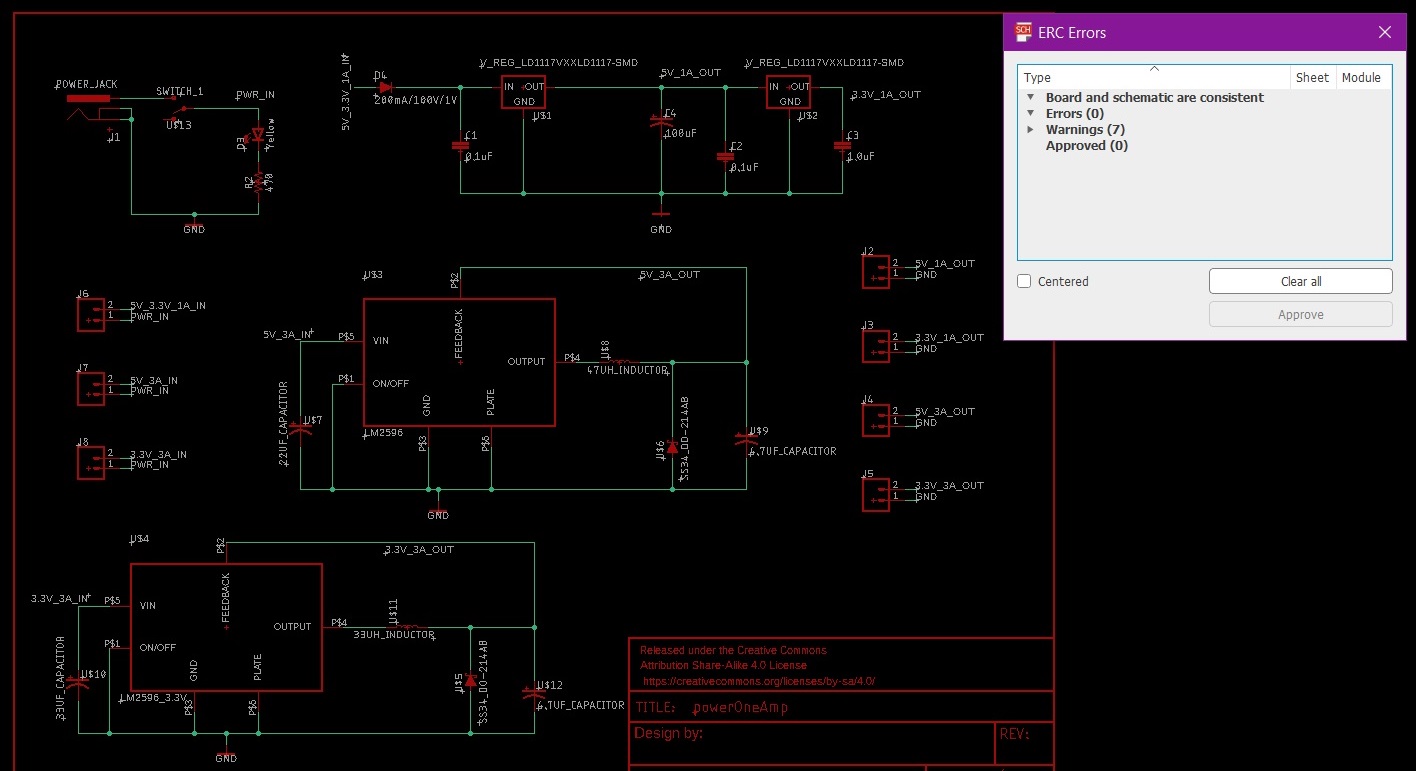

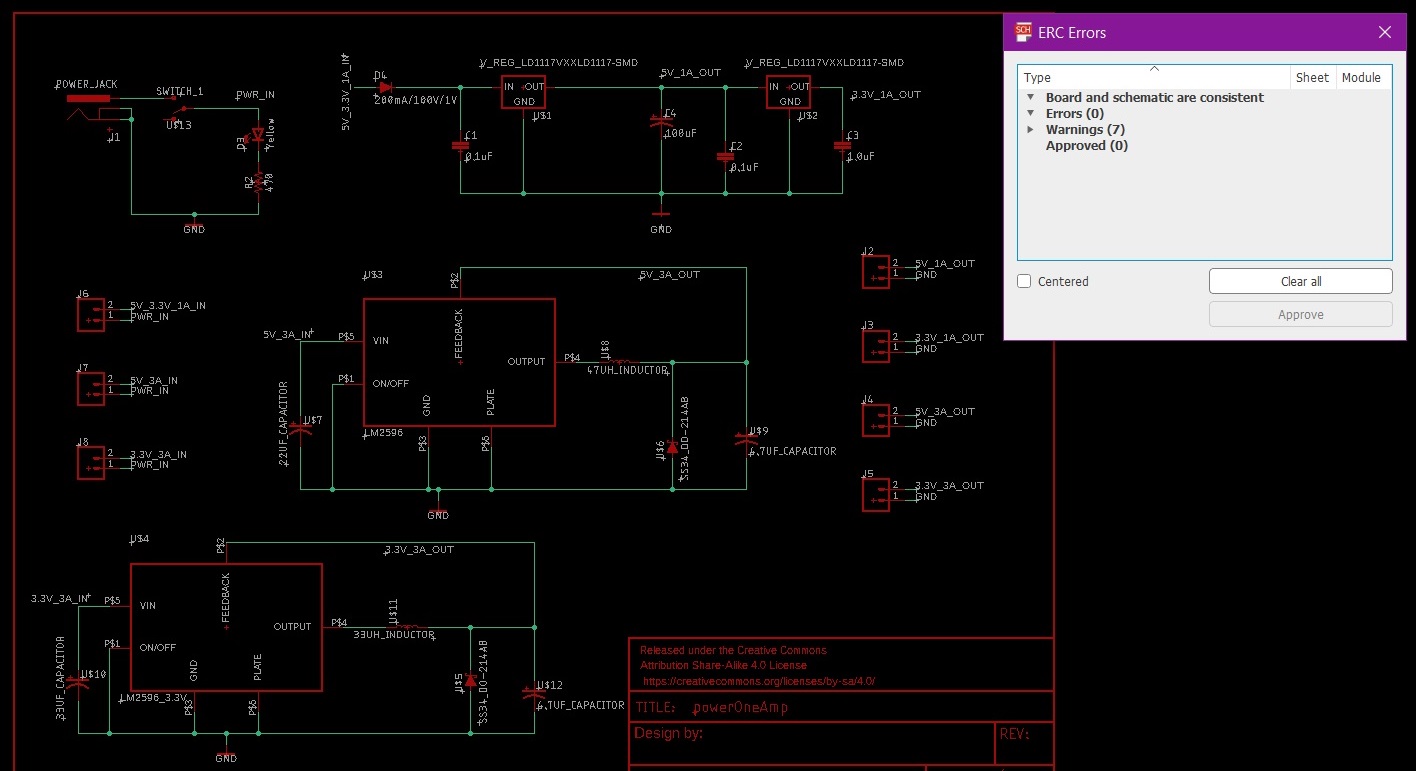

schematic of the circuit board can be seen in figure 1. The schematic

was then checked for potential errors with an ERC check. Once all the

errors were cleared, the board was constructed and the physical

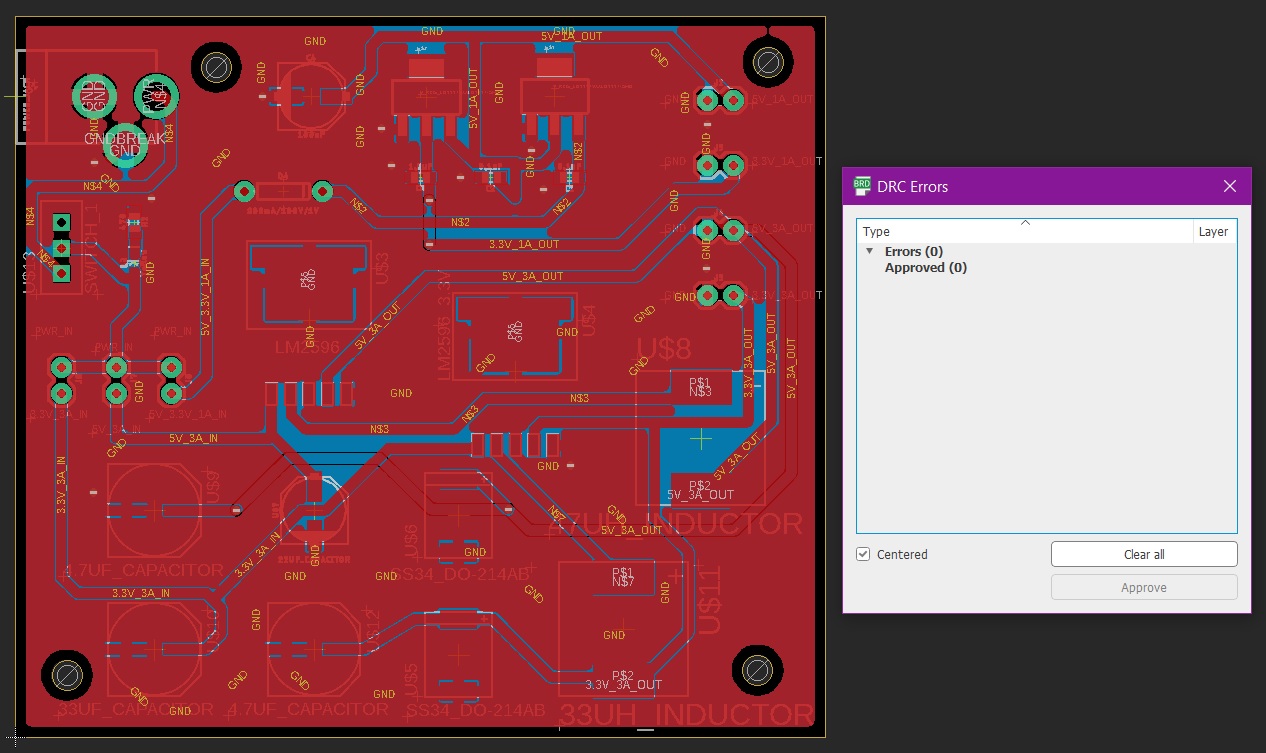

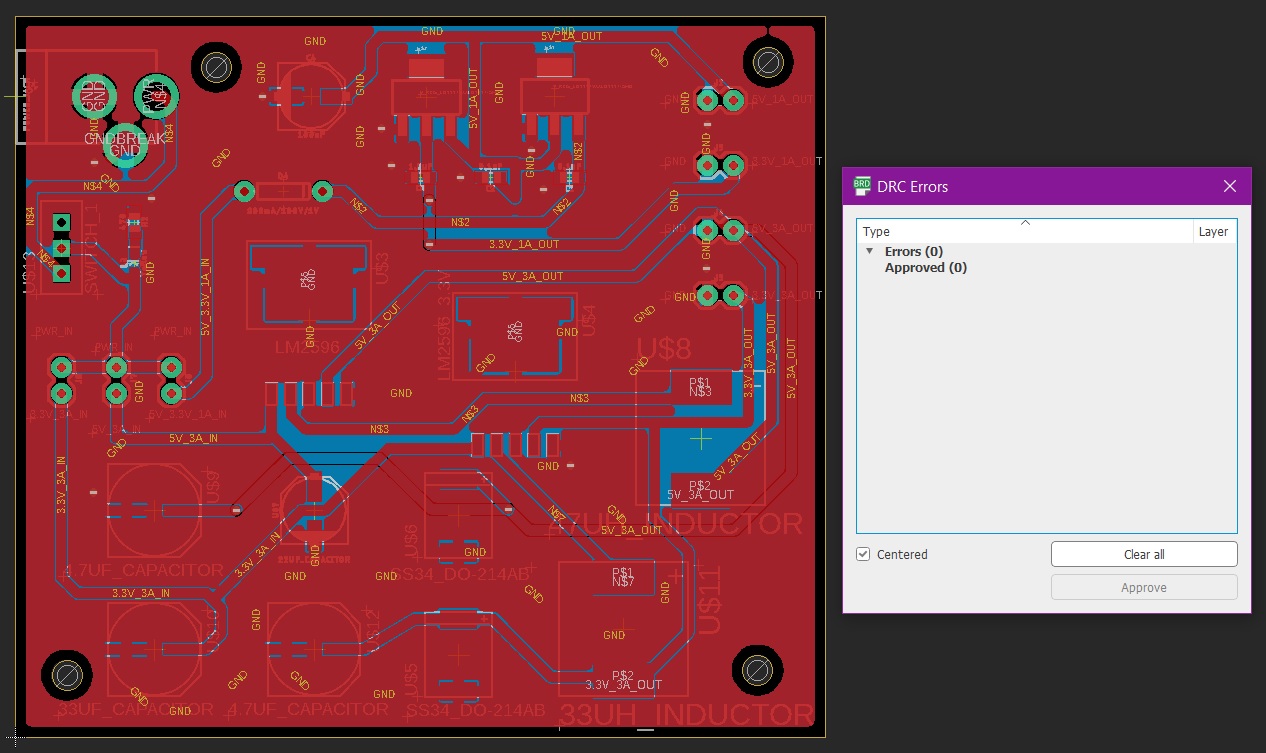

connections were made. The board was then checked for errors with a DRC

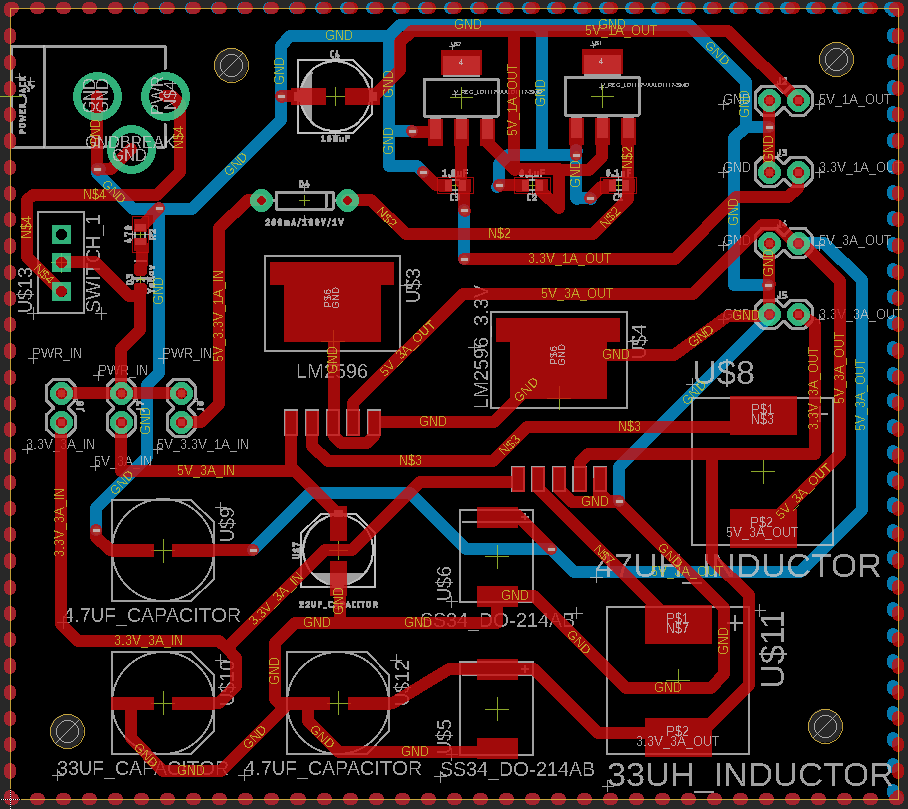

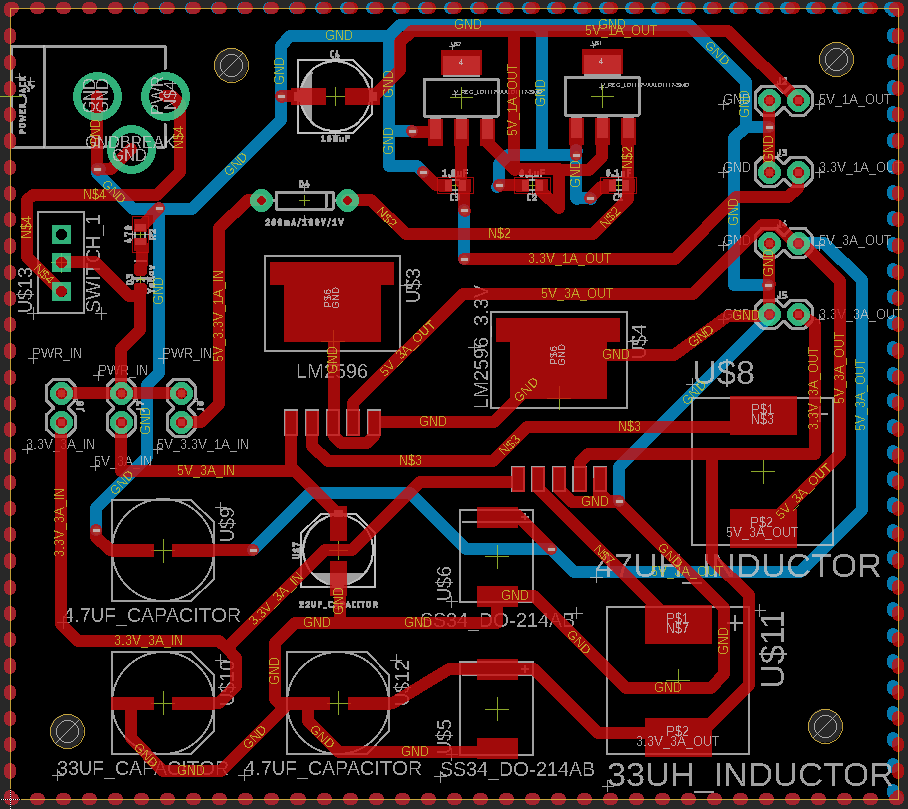

check. Figure 2 shows the completed board layout. Figure 3 shows the

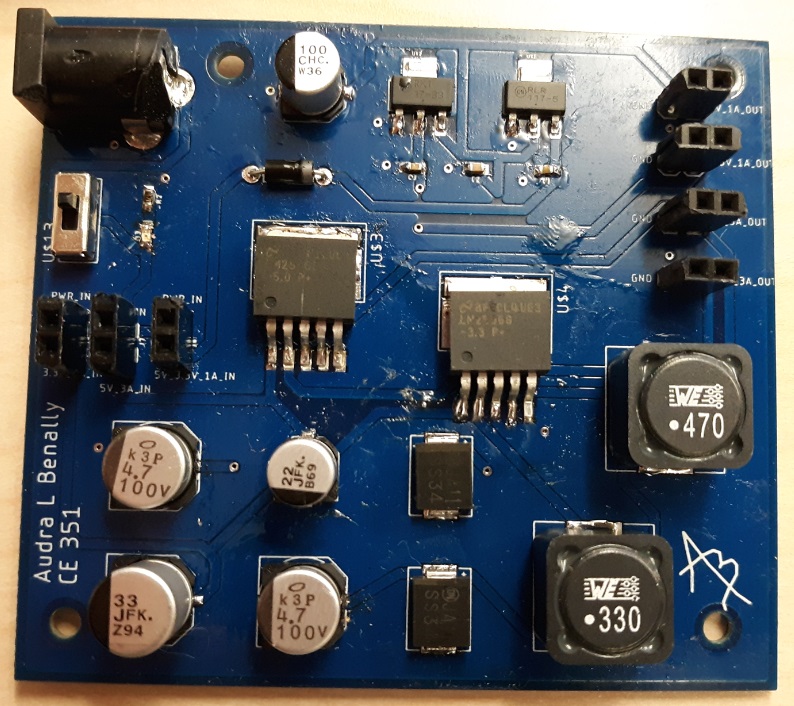

DRC check results. Once the board came in from production, the

components were soldered according to the schematic. The board was then

tested for accuracy; The results can be seen in Figures 6 - 9.

4. Results:

Figure 1. The completed schematic with 0 ERC Errors.

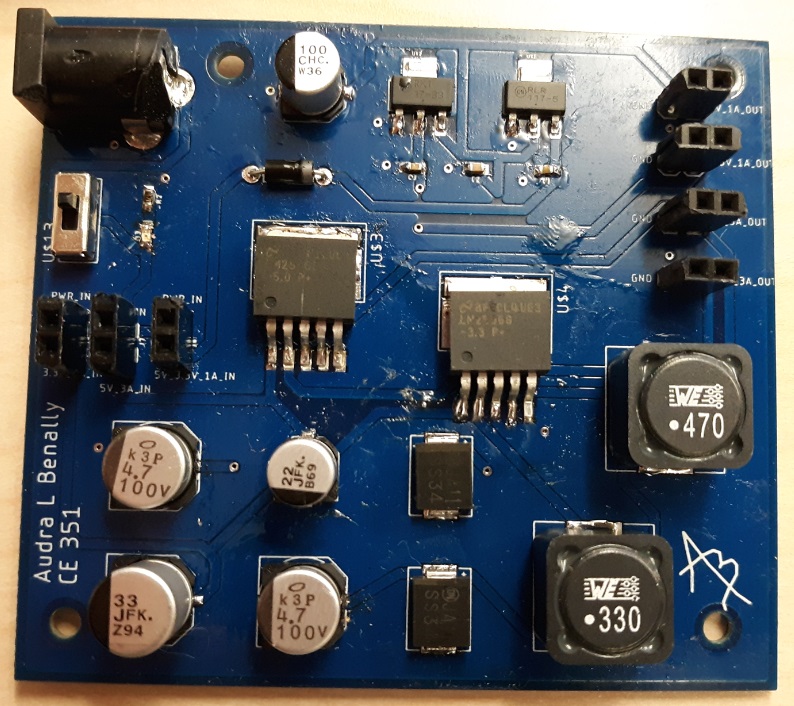

Figure 2. Finished board.

Figure 3. 0 DRC errors in board layout.

Figure 4. Completed PCB.

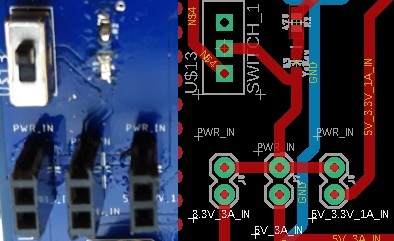

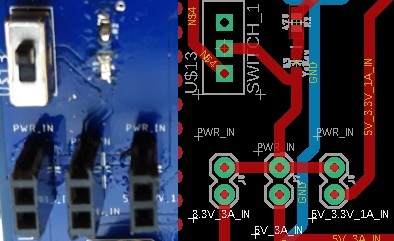

Figure 5. The

power in pins. On the left: 3.3V 3A IN. Middle: 5V 3A IN. Right: 5V

3.3V 1A IN.

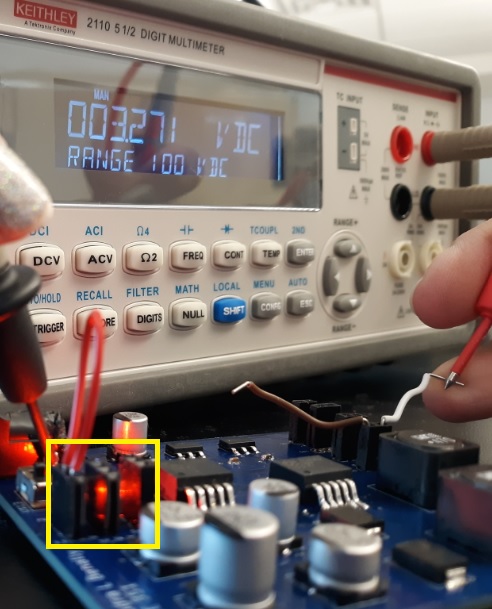

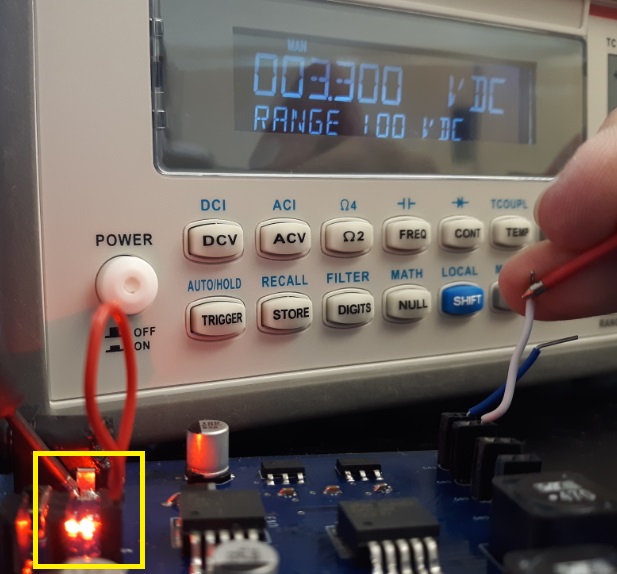

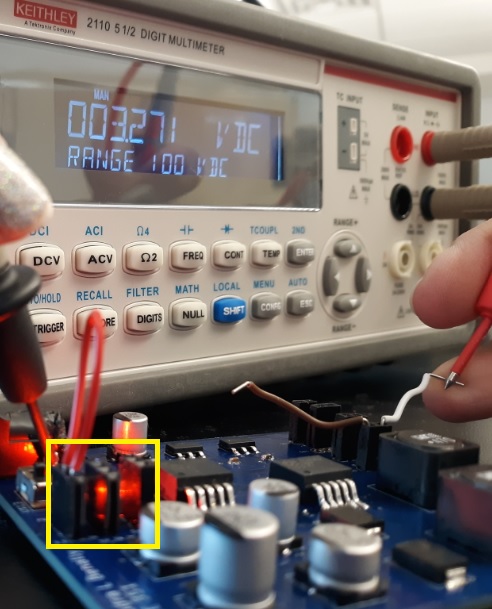

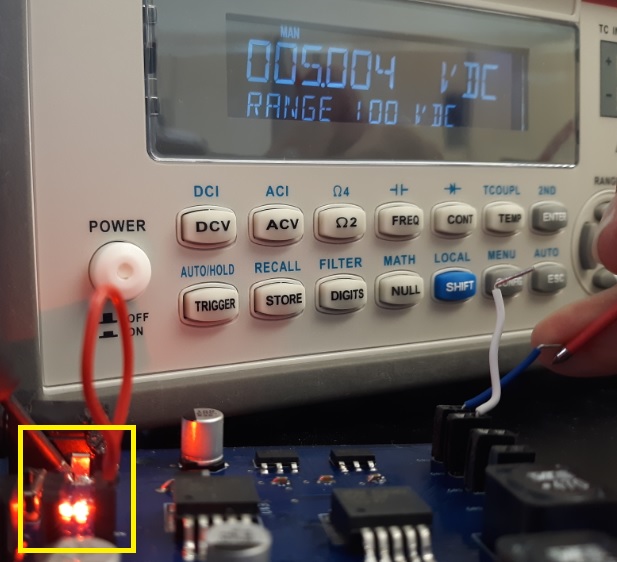

Figure 6. The

far left 3.3V 3A in pin is shorted to the power input and the ouput

shows 3.271V.

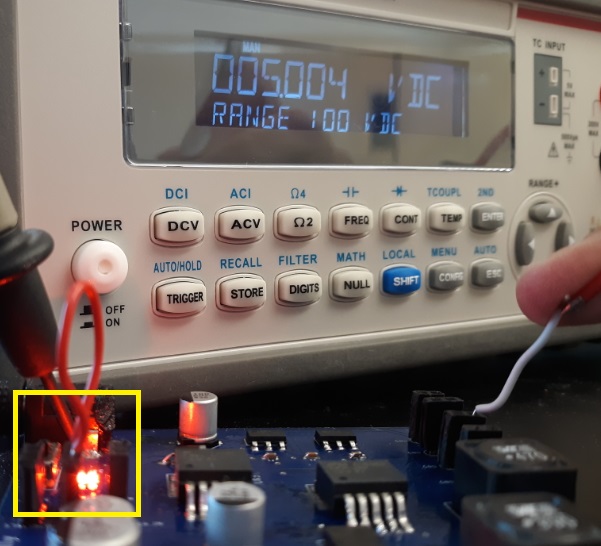

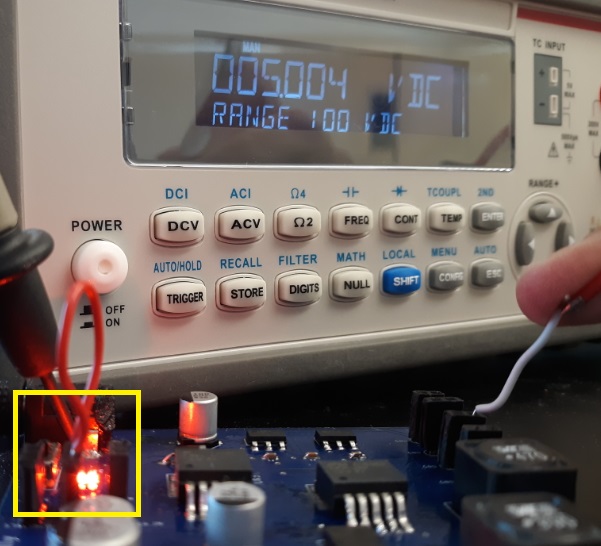

Figure 7. The

middle 5V 3A in pin is connected to power and the ouput correctly reads

5.004V.

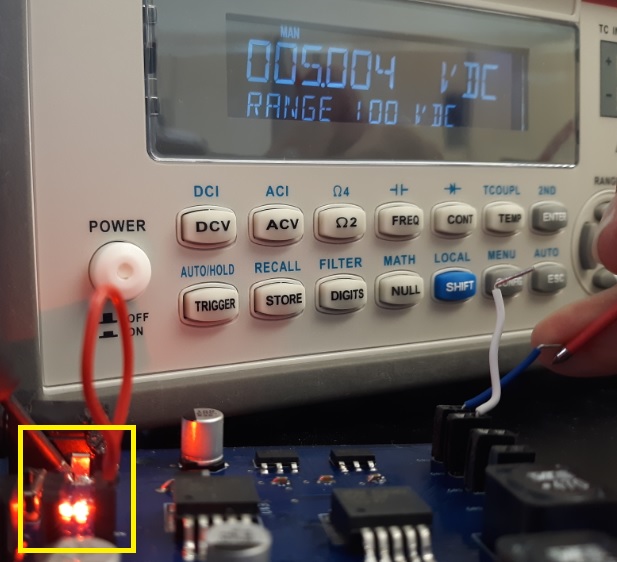

Figure 8. The

right 5V 3.3V 1A in pin is connected to power and the 5V output is

probed and shows 5.004V out.

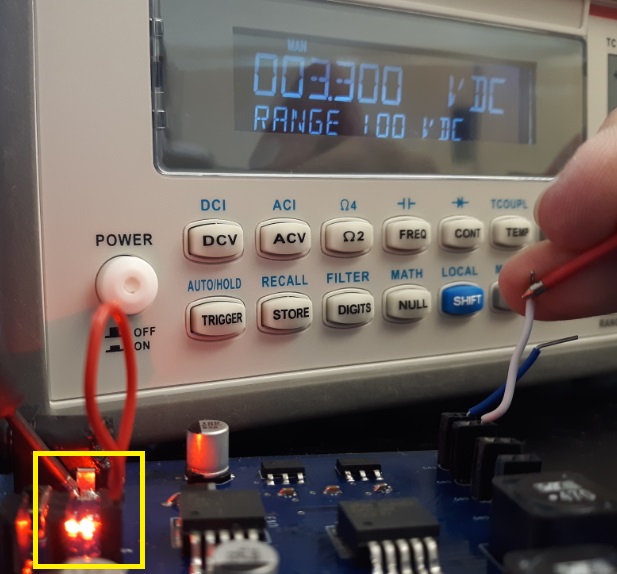

Figure 9. The

right 5V 3.3V 1A in pin is connected to power and the 3.3V ouput is

probed and shows 3.300 V.

5. Discussion

This introduction to Eagle PCB

was incredibly informative. The tutorials provided just enough

frustration to drill the experience into my head. The ERC and DRC

checks were very undescriptive so playing with the different

components, including the library devices, was particularly

educational. Redoing the components that I had done incorrectly the

first time was enlightening. The videos were very easy to follow. The

wiring of the physical components of the board was my

favorite part and especially enjoyable. This was my first time

soldering anything. It was rocky in the beginning; I completely missed

a pin for my LM2596 3.3V chip and I put a couple diodes in backwards.

After much debugging, the circuit board was functioning correctly with

the results shown in figures 6 - 9. I really enjoyed this entire lab.

The product of my hard work will be

well deserved and properly cherished.